In this competitive world, all organizations are trying to reduce the cost of operation and maintenance of marine engines and diesel generating sets.

It is generally observed that the prices of spare parts are exorbitant and in certain cases the delivery offered is long. RA Power Solutions Pvt. Ltd. supplies spare parts procured directly from OEMs and guarantees the satisfactory performance. Our prices are lowest in the industry.

RA Power Solutions Pvt. Ltd. also deals in reconditioned marine engine and diesel generating sets spare parts which are calibrated by our experienced technicians in our state of art, workshop having latest instrumentation and equipments for undertaking repairs. Some of the products offered by us are as under:

Marine Engine Spares

High-capacity marine engine spares are supplied for reputed engine manufacturers like Wartsila, Mak,Deutz, Bergen, Niigata, Himsen, Allen, Stork, Fiat, MWM, Hanshin, Caterpillar, etc. The spares parts are procured from the OEM. Each part is subject to calibration and inspection at our works by the experienced technicians. Inspection report is prepared.

RAP also supplies reconditioned spare parts procured from the ship breaking yard and diesel-generating power plant which have become abundant due to availability of alternate source of energy. Parts are reconditioned at our works and are supplied with guarantee. We also stand guarantee for lowest price in the industry.

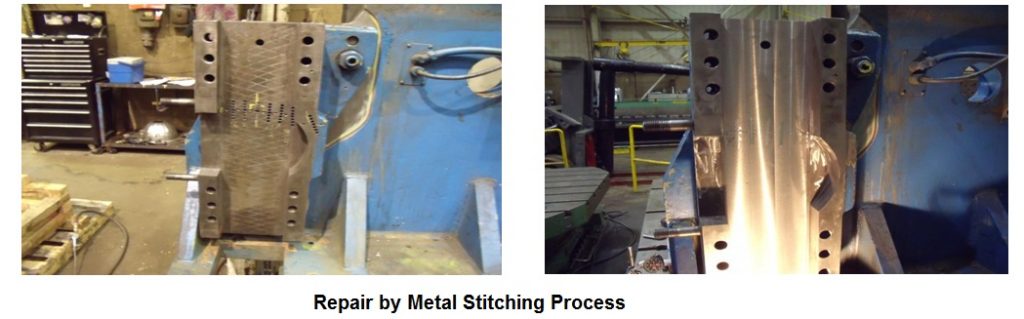

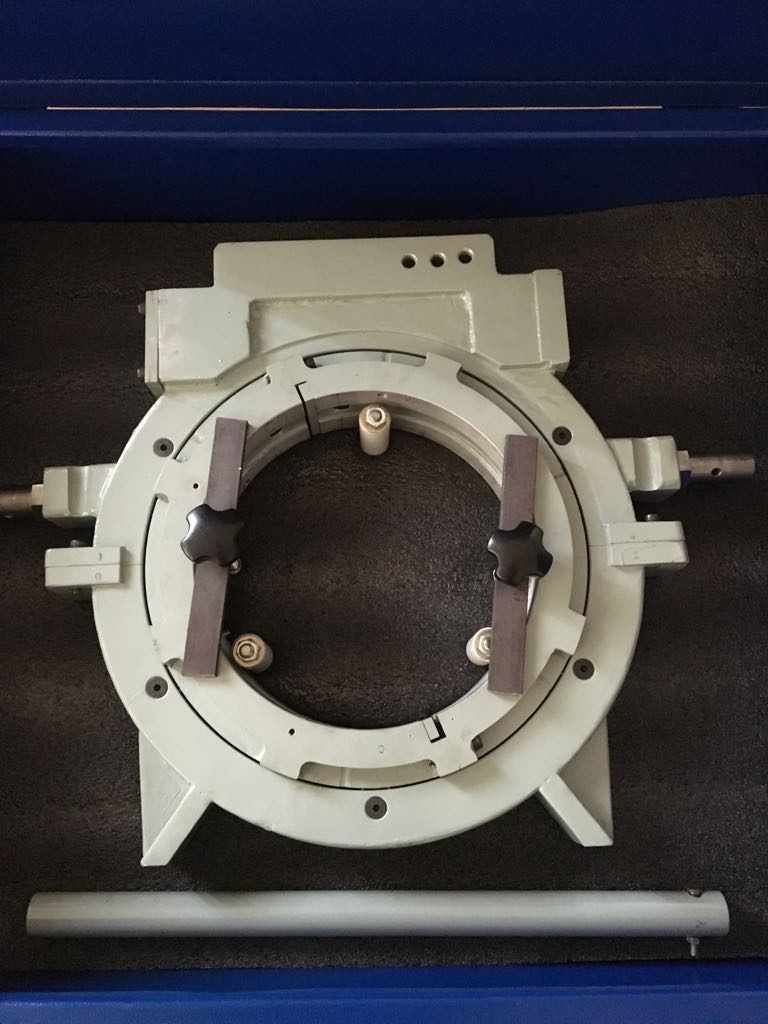

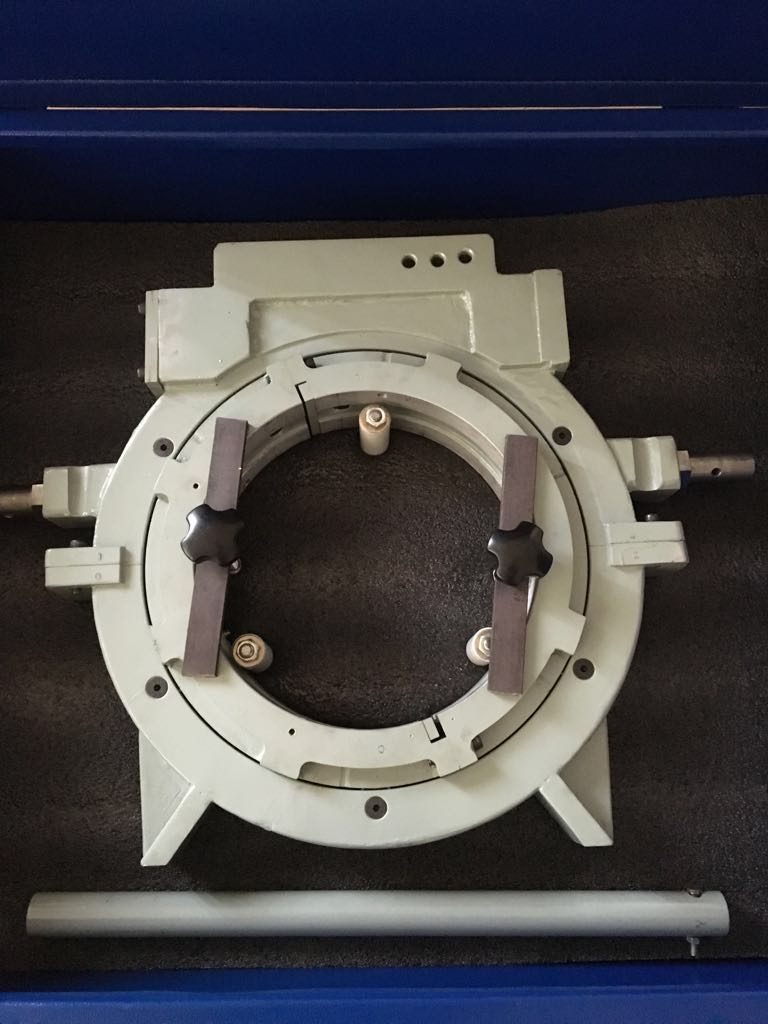

Onsite Crankshaft Grinding Machine

We manufacture latest design of onsite crankshaft grinding machines ranging from 40 mm to 700 mm diameter. Ours is the only company which can execute repair of crankshaft by grinding/polishing onboard the vessel while it is sailing. This is possible only due to the vibration less latest technology crankshaft grinding and polishing equipment designed and manufactured by us and technicians having seaman passport.

We are cost-effective and can dispatch our team of technicians with onsite crankshaft grinding equipment within 6 hours notice.

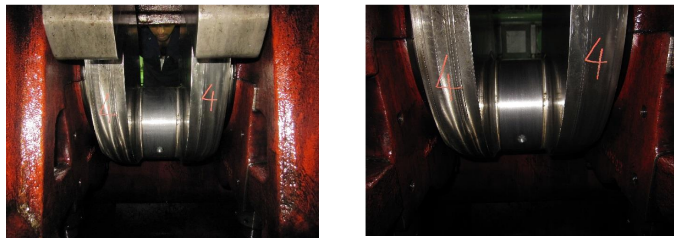

Second-Hand Crankshafts

Second-hand crankshafts of most of the popular make of engines are available ex-stock. It is a policy of the company to polish all the CR pins and main journals as these facilities are available in house the inspection reports for taper, ovality, hardness, crack detection, alignment, etc. are prepared and submitted with the crankshaft.

We have been selling second hand and reconditioned crankshafts for last 36 years and have sold second hand crankshafts exceeding 160 numbers all over the world. We are priced lowest in the industry.

Fresh Water Generator

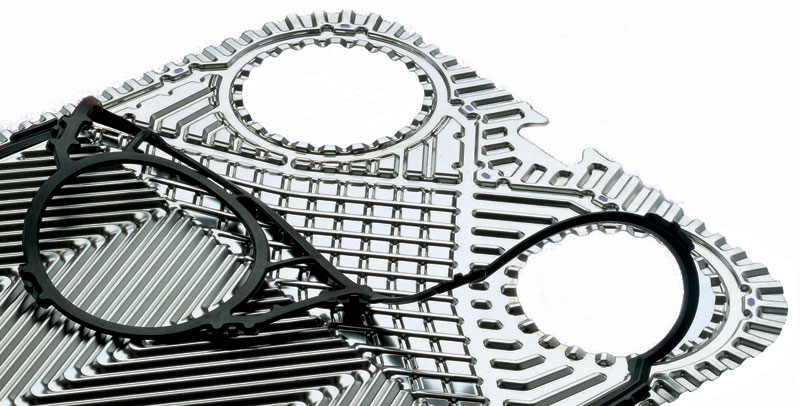

Fresh Water Generator, heat exchangers, purifiers are procured from ship breaking yards andabondened diesel power plants. These equipments are fully reconditioned by changing rubber components, bearings, and other spares. All equipments are put on trial and supplied with guarantee of lowest price in the industry.

Gaskets

Gaskets, Rubber gaskets for all alpha laval equipments like fresh water generator, heat exchangers, and purifiers are available in stock. Gaskets of other make of equipments are also manufactured. We can also develop the gaskets as per the requirement of the client or as per the sample. Performance is guaranteed and gasket are priced nearly half of the OEM price.

White Metal Bearing

We manufacture white metal Babbitt bearing for rotor shaft, crankshaft, alternator shaft, turbine shaft and all application. The new white metal Babbitt bearings are manufactured up to 1500 mm diameter. Close tolerances are maintained.

We regularly export white metal Babbitt bearings for different applications all over the world. We are cost-effective and have experience of more than 45 years in this field.

Tri-Metal Bearing

After grinding of crankshaft under size and special size tri metal bearings for crankpin and main journal are required. RA Power Solutions Pvt. Ltd. manufactures tri metal bearings as per the requirement. We also have facility to develop and manufacture bearings in case the quantity is large.

We have new and reconditioned spare parts of the following make of engine:

- MAN-B&W

- Sulzer

- Wartsila

- Mak

- Deutz

- Pielstick

- Mitsubishi

- Daihatsu

- Yanmar

- Bergen

- Niigata

- Himsen

- Allen

- Stork

- Fiat

- MWM

- Hanshin

- Caterpillar

- SKL

- Ruston

- Paxman

- Crepelle

- Mirrlees

- Alco

- ABC

- Nohab

For more information on spare parts of diesel engine, Wartsila Marine Diesel Engine, reconditioned spare parts, diesel engine spare parts manufacturers, and onsite crankshaft grinding please email us at rajshahani@rapowersolutions.com, or info@rapowersolutions.com, or call us at +91 9582647131 or +91 9810012383.