Engine blocks, casting and most of the parts are manufactured of common material like cast iron. Cracks developed in cast iron parts are most difficult to undertake repair by welding process as it needs pre-heating of the cast iron prior to the welding. In certain cases it can cost additional stresses resulting to the damage of casting.

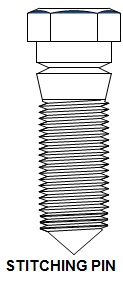

It is proven that metal stitching and metal locking has advantage of repairing cracks in cast iron casting due to cold process using different profile and material of stitching pins and locks without applying any heat as in case of welding.

RA Power Solutions Pvt. Ltd. undertakes metal stitching and metal locking of casting and has successfully repaired various major components of high capacity diesel engine.

Application includes repair of Engine Block, Cylinder Head, Generators. Turbo Chargers, Turbine Casing, Gear Box Housing, Pump Casings, Compressor Crank Cases, Forgings Hammer, Lathe / Press/ Milling/Boaring etc .M/c. Other all Casting Equipments etc.

In last 36 years more then 650 jobs of crack repair have been successfuly executed.

For more details regarding crack repair by metal stitching, engine block repair, cold metal lock stitching, and cast iron by metal lock & metal stitching, please email us at rajshahani@rapowersolutions.com, or info@rapowersolutions.com, or call us at +91 9582647131 or +91 9810012383.