Availability of required spare parts play an important role in Engines, compressors, and heavy industries. Our Stock consists of spare parts of all makes and models of engines including Daihatsu, Yanmar, MAN B&W, Wartsila, Cummins, Caterpillar, etc.

We supply TEIKOKU pump spare parts anywhere in the world and these spare parts are genuine and each spare part is inspected before giving to any of our clients.

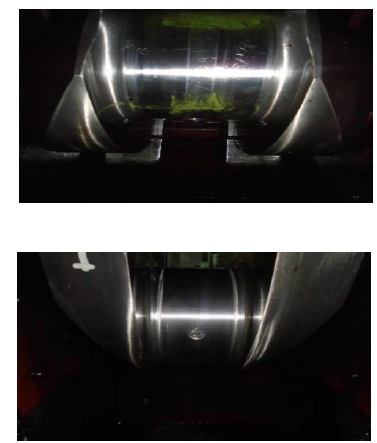

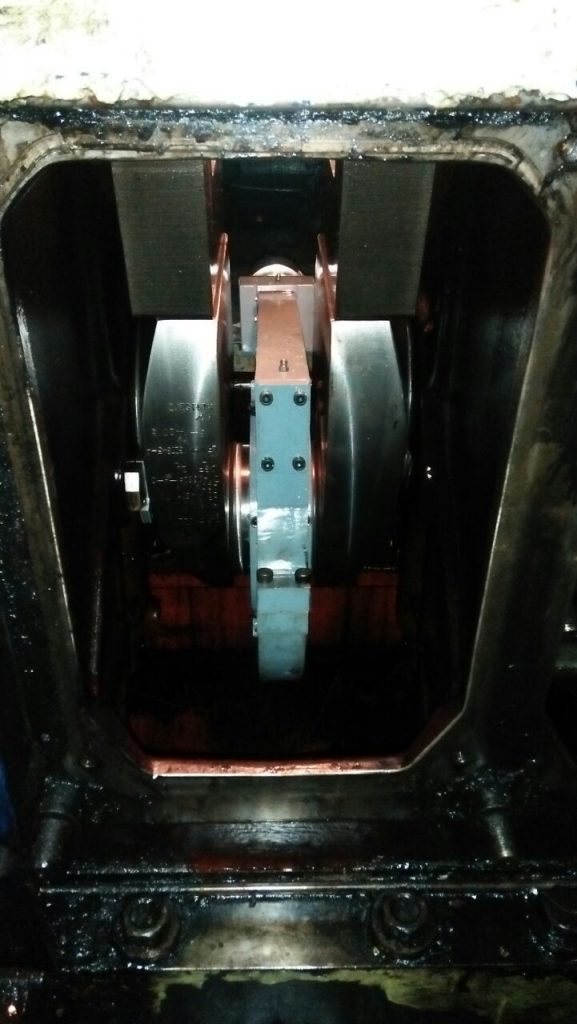

We are highly knowledgeable and experienced to provide any spare parts that you need and we are readily available to fulfill all your needs related to spare parts of TEIKOKU pump. We as a supplier ensures that spare parts we provide are cost-effective and most importantly perform well as per client’s requirements. We are also leaders in providing services like crankshaft grinding, crankshaft repair, and crankshaft polishing. We can do urgent delivery of spare parts of all makes and models of engines.

FOLLOWING SPARE PARTS OF TEIKOKU PUMP ARE AVAILABLE WITH US:-

3X3, 5X3, 5X4, 5X6, 6X5,8X6, 10X10, 12X12, 14X14, 16X16, 32X20MS, 32HC-Am,Bm, 32MS-B, 50X25MSS, S0CSm, 50MS A,B, 50BF-A5m, 50- 2SL, 50MSS-Bm, 65X50, 65CSm, 80CSm, 100X50, 100HC-B, 100MS-B, 125X100, 125HC-Bm, 125VCS-A, 150VCS-A, 150-2VCS-A-NV 200 X100, 200VCS-Am, 200VCS-A-NV, 200VCB-B-NV, 250X125, 200VCB Bm-NV, 200VCD-Am, 350VCD-Bm & etc …

We have been regularly executing the repairs in Argentina, Bahamas, Barbados, Bermuda, Bolivia, Brazil, Canada, Chile, Colombia, Costa Rica, Cuba, Dominican Republic, Ecuador, El Salvador, Guatemala, Guyana, Haiti, Honduras, Jamaica, Mexico, Nicaragua etc.

This blog is written by Mr. Raj Shahani (Managing Director of RA Power Solutions India Pvt. Ltd.).

Mr. Shahani is a highly experienced business leader with rich experience of more than 40 years in the field of Power, Heavy, and Shipping industry. He is Technical Adviser to many shipping and heavy industries across the globe.

Mr. Shahani is one of the most enthusiastic professional and he has all the brilliance of an exemplary leader. Mr. Shahani is an extremely effective coach and mentor of teams and is adept at providing leadership in a global, cross-cultural environment.

For more details on our other services like crankshaft grinding and onsite crankshaft repair contact us at rajshahani@rapowersolutions.com, info@rapowersolutions.com, or call us at +91 9582647131 or +91 9810012383.