It is observed that cracks repair in cast iron components develop due to exposure to excessive heat or mechanical failures. Sometimes it is difficult to arrange for the new part due to long delivery or exorbitant price.

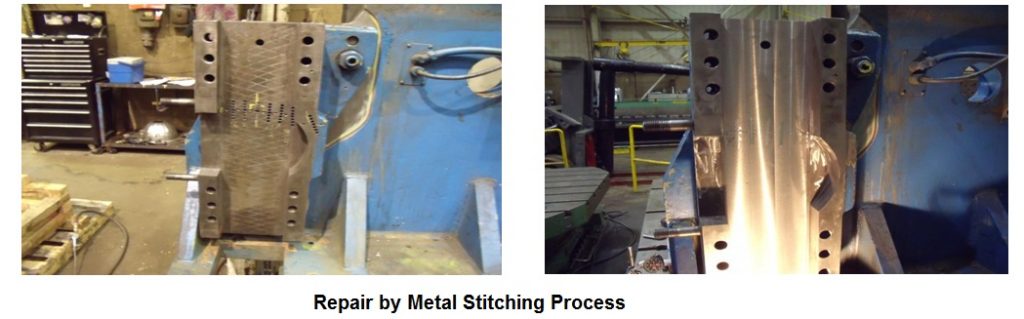

RA Power Solutions undertakes repair of cracked cast metal or aluminium components by metal stitching and metal locking process. It provides permanent crack repair solutions without the generation of heat associated with the welding process. The main advantage of cracking or damaged cast iron or aluminium components by metal stitching and metal locking is that it can be performed onsite avoiding the considerably high cost of labour for disassembly of the equipment and transport to the designated workshop.

The repair of cracks cast metal by metal stitching and metal lock process restores the surface area to the original dimensions and profile. Very rarely there is a requirement for machining. The repairs are also watertight and gas-tight.

RA Power Solutions with experience of more than four decades. We have experienced technicians who have undertaken the most complex crack repair jobs through metal stitching and metal lock processes. The technicians carry pneumatic portable tools and consumables to the site. We have executed thousands of repairs of cracked components, a broad description of which is as follows:

- Repair heavy earthmoving and mining machinery.

- Repair of high-capacity turbines, alternators, turbocharger casings, and parts.

- Cracked engine blocks, cylinder heads, pistons, and cylinder liners.

- Heavy-duty industrial machine.

The consumables used by RA Power Solutions for the repair of crack cast metal by metal stitching and metal lock have the following properties which result in permanent repair with a guarantee.

I) Locks:

The locks of different designs are used in the process of repair of cracks by metal lock and metal stitching according to the intensity of the crack, length and thickness of the casting.

The locks used by us are made of precision-cut high-grade steel and are able to withstand high tensile forces more than the original casting.

II) Stitching Pins:

The stitching pins used by us have special threads which make the process failure-free. The pins are manufactured out of high-grade steel and have higher tensile strength than the cast iron.

For your requirement of crack repair on-site in a Power Plant or onboard a vessel, you may contact RA Power Solutions. All our technicians have valid CDC and can fly to any destination in the world on short notice.

For more details on fixing a cracked engine block, metal surgery process, repair crack cast iron, engine block repair, crack repair of components, and cast iron engine block crack repair please email us at rajshahani@rapowersolutions.com, or info@rapowersolutions.com, or call us at +91 9582647131 or +91 9810012383.