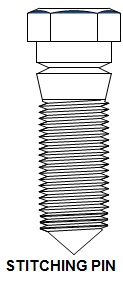

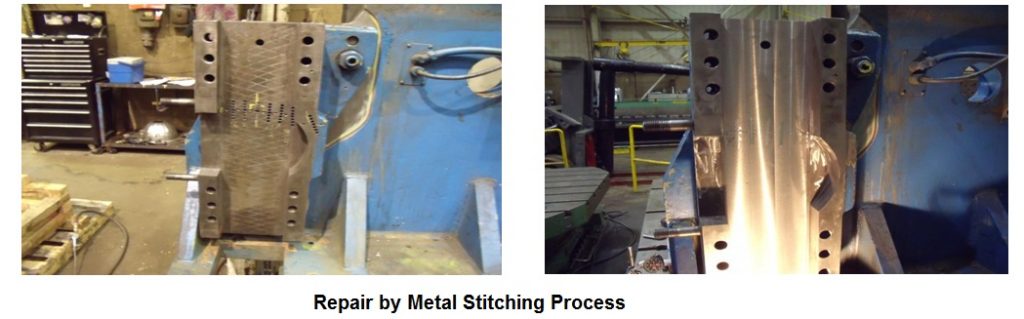

Metal locking and metal stitching is a process of repair of cast metals having different metallurgy without the necessity of wielding. Metal locking and metal stitching is a cold and proven method of repair of cast iron and cast steel components.

The advantage of crack repair and broken casting by metal locking and metal stitching is that it can be carried out at the site anywhere and it even does not require dismantling of the equipment in most of the cases this results to considerable saving of time and money. Crack and broken casting repair by metal stitching and metal locking is proven and is old method for crack repair it is widely used for heavy-duty plant and equipment, ship engine, heavy-duty forging presses, etc.

We regularly execute crack repair by metal locking and metal stitching of following parts:

Engine Block, Cylinder Head, Generators, Turbo Chargers, Turbine Casing, Gear Box Housing, Pump Casings, Compressor Crank Cases, Forgings Hammer, Lathe / Press/ Milling/Boaring, etc .M/c. all Cast equipment etc.

RA Power Solutions is a leading provider of metal locking services. We have a team of experienced engineers and technicians who are skilled in using this technique to repair a wide variety of castings. We have a proven track record of success, and we are confident that we can provide you with a high-quality repair that will meet your needs.

If you have any questions about metal locking and metal stitching services please contact RA Power Solutions. We would be happy to answer your questions and discuss your specific needs.

For more information on cold metal lock stitching, metal stitching service provider, metal stitching cast iron, crack repair by metal stitching, metal locking, and metal stitching of engine block email us at rajshahani@rapowersolutions.com, or info@rapowersolutions.com, or call us at +91 9582647131 or +91 9810012383.