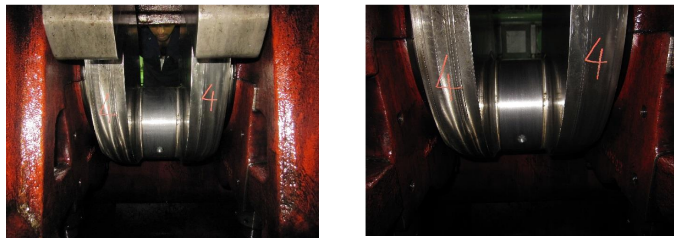

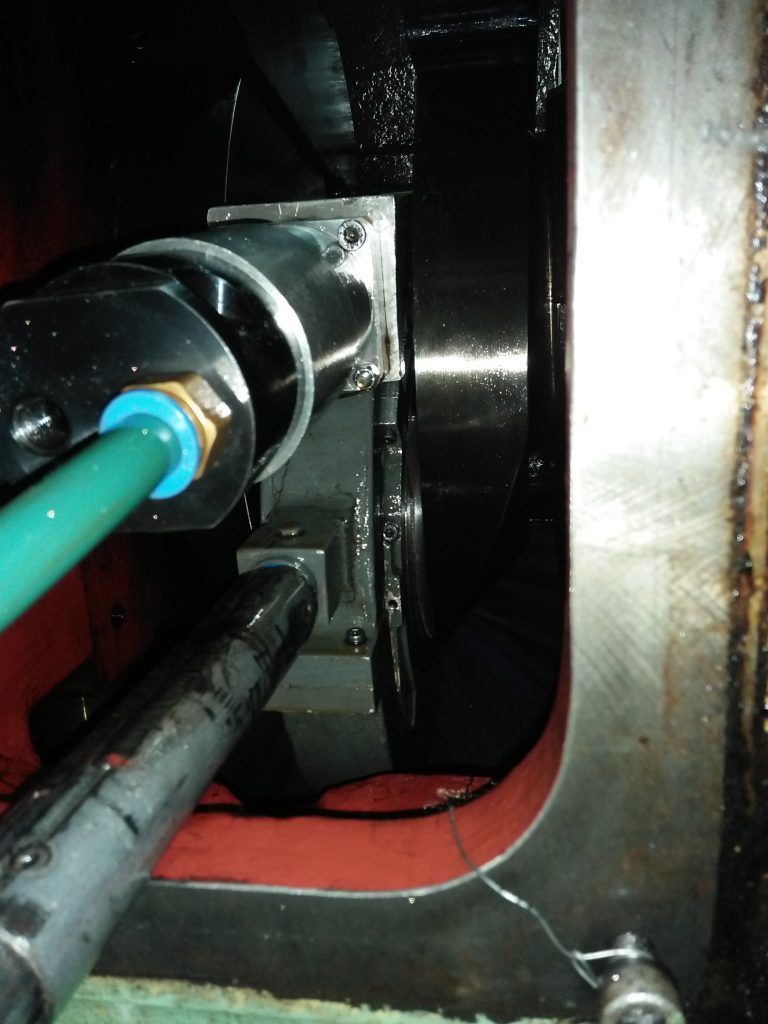

RA Power Solutions Pvt. Ltd. can easily undertake crankshaft repair on board a vessel while it is sailing by using special equipments.

We can undertake crankshaft repair up to the diameter of 700 mm while the vessel is sailing in high seas in anchorage or at berth. This result to considerable saving for ship repairs as no time is wasted for crankshaft repair as it does not require any anchorage or berth.

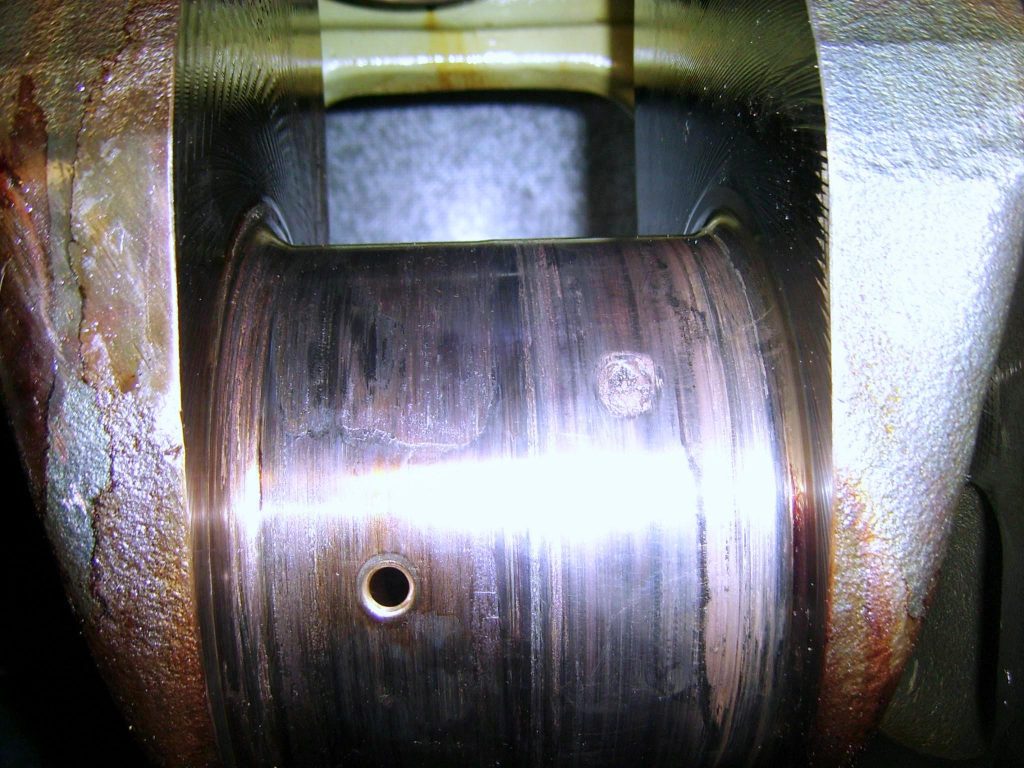

RA Power Solutions having 37 years of experience have executed more than 10,000 jobs of repair of crankshaft successfully which is a record.

The crankshafts which have been even rejected by the manufacturers are successfully repaired by us using various process/special equipments which we are learned from our experience. All the repair of crankshaft executed by us is guaranteed for the satisfactory performance. The tolerances as stipulated in the manual are strictly maintained.

Most of our technicians have seaman book and they can sail to any part of the world.

For more details regarding in situ crankshaft grinding, crankshaft repair on board a vessel and onsite crankshaft repair please email us at rajshahani@rapowersolutions.com, or info@rapowersolutions.com, or call us at +91 9582647131 or +91 9810012383.