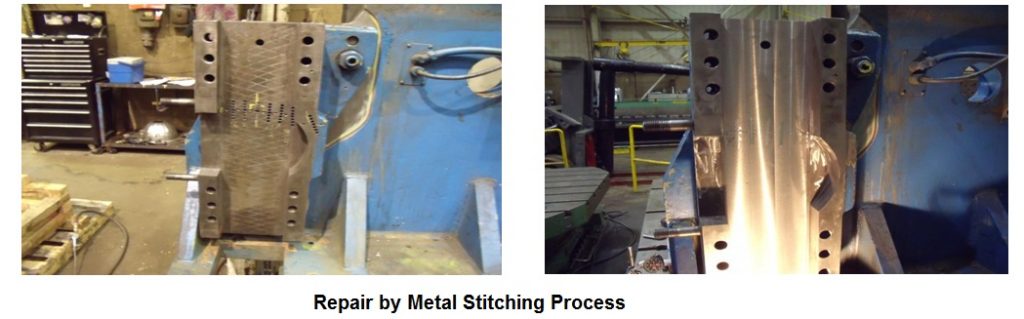

Repair of cracks developed in commonly used industrial castings and metal is possible to repair by cold method called lock and stitch. It is also known as metal stitching and metal locking. In case of cast iron equipments and parts damaged in to pieces.

RA Power Solutions Pvt. Ltd. undertakes repair by lock and stitch process which is cold method as no heat is generated. Crack repair by lock and stitch method in cast iron is proved to be of great success in comparison to the crack repair by welding.

In case of critical cast iron components like engine block, main journal housings, cylinder heads, turbine casings crack repair by metal stitching is highly recommended as it does not develop any misalignment of the casting or shrinkage. We undertake crack repair of cast iron for last more than 37 years on time, within budget and with experienced technicians.

Cast iron repair by metal stitching and metal locking process have following main advantages:

- Repair of broken casting or crack developed in casting irrespective of its length is possible on site without dismantling the equipment.

- Saves replacement of parts or equipments in totality and reduces downtime.

- Cast iron repair by metal stitching and metal locking is the only process which restores strength in cast iron beyond the original casting.

- Metal stitching and metal locking is the only method known to be successful in replacing of the large pieces of broken casting with new piece.

- Metal stitching and metal locking is the process which caters to heavy industry.

RA Power Solutions Pvt. Ltd. is the only company which can undertake crack repair by Lock and stitch method while vessel is sailing.

For more details regarding Engine Block of MAN Diesel Engine please email us at rajshahani@rapowersolutions.com, or info@rapowersolutions.com, or call us at +91 9582647131 or +91 9810012383.