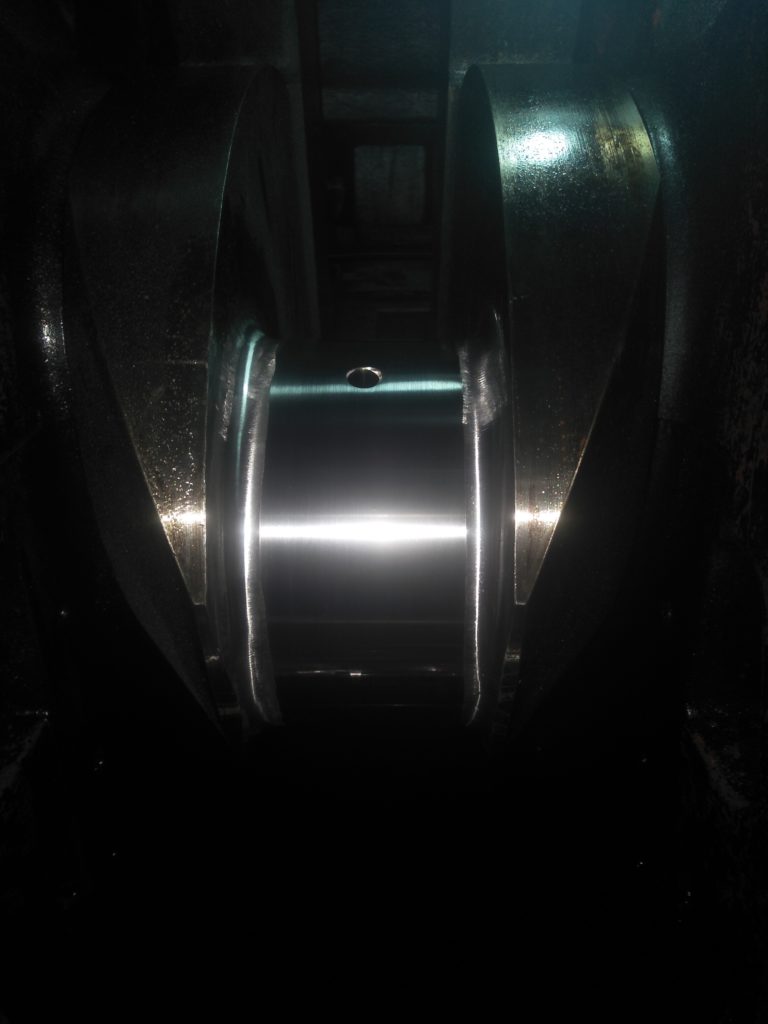

Crankshaft grinding machines are designed to maintain the accurate tolerances as per the engine manufacturer’s recommendation.

Generally, it is observed that even for the higher diameter of crankpin and main journal of the crankshaft the tolerances do not exceed more than 0.05mm in order to achieve such close tolerances of crankpin and main journal of crankshaft RA power designs and manufactures on-site crankshaft grinding machine which has the capability to maintain the close tolerance of even 0.01mm/0.02mm which is far better than the close tolerance specified by the engine manufacturers.

The on-site crankshaft grinding machine and crankshaft polishing machine manufactured by RA power solutions has the following features:

- Crankshaft grinding machine is designed in a way that it can be inserted from the inspection window of the engine block thus there is no need of removal of the crankshaft from the engine block.

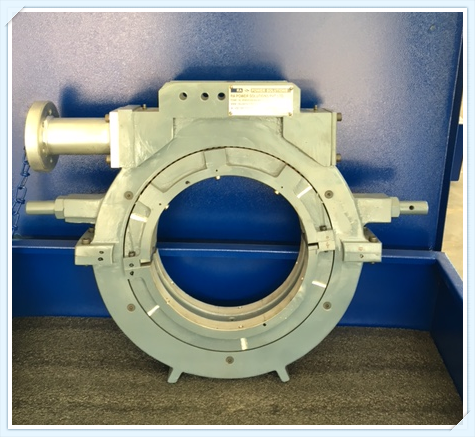

- In case of space restrictions, RA power has the capability to design the equipment according to the space available on site for grinding or polishing of crankshaft/turbine/alternator shaft/rotor shaft etc…

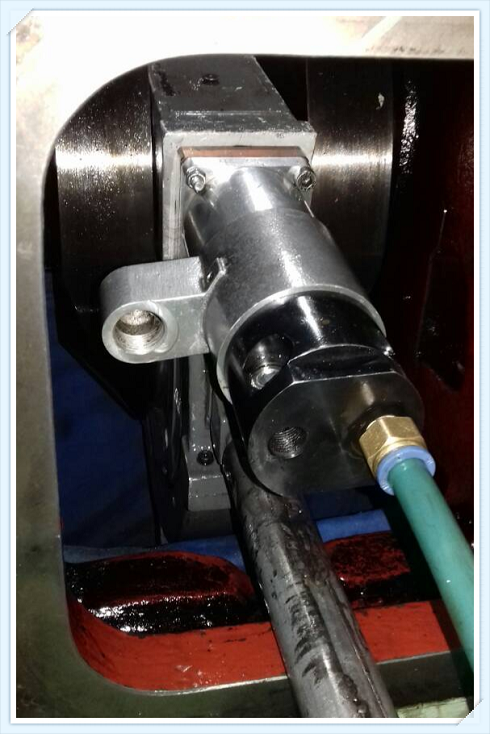

- The on-site crankshaft grinding machine is lightweight portable and can be easily carried to the site all over the world. The crankshaft grinding machine is packed in the suitcase and is carried as accompanied baggage accepted by all international airlines.

- The main body of crankshaft grinding equipment is manufactured out of titanium alloy which is lightweight and can absorb the vibrations this feature of crankshaft grinding machine facilitates RA power technicians to undertake crankshaft repair on board the vessel while it is sailing, maintaining the close tolerances within 20 microns.

- Crankshaft grinding machine designed and manufactured by RA power can presently work up to 700mm diameter which we are in process of extending up to 1000mm.

Conclusion

RA Power has sold more than 70 crankshafts grinding machines all over the world which are performing satisfactorily the cost of the machine is low and is affordable for repair workshop, shipping company, power plants, etc…

For more information on onsite crankshaft polishing machine, crankshaft grinding machine, or onsite grinding and repair by crankshaft machine email us at rajshahani@rapowersolutions.com, or info@rapowersolutions.com, or call us at +91 9582647131 or +91 9810012383.