We were approached by a company based in Greece reporting the failure of a crankshaft of auxiliary engine on one of their vessels operating in the Gulf.

It was reported that the accident resulted in the failure of the bearing of crankpin no. 1, 3, and 6.

DETAILS OF YANMAR 6N18AL-DV ARE AS FOLLOWING:-

| S. NO | Crankshaft Details | |

| 1 | Engine Make | YANMAR |

| 2 | Engine Model | 6N18AL-DV |

| 3 | Crankpin Diameter Standard | 145 mm |

| 4 | Crankpin Bearing Width | 65 mm |

| 5 | Name of Vessel | MV GULF Traders |

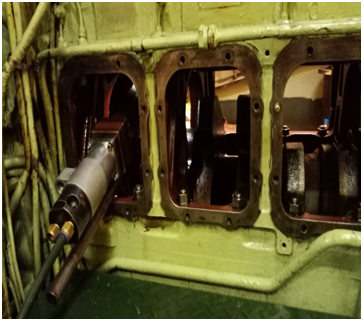

Our team of two technicians boarded the vessel in short notice and requested the chief engineer to open the connecting rod of all six crankpins.

THE CRANKPINS AFTER CLEANING WERE SUBJECT TO DIMENSIONAL INSPECTION AND FOLLOWING DIMENSIONS WERE OBSERVED:-

STANDARD DIMENSION: 145.00 mm

STANDARD /SPECIFIED NO

SIZE OF CR PINS

| A | Aa | C | Cc | B | Bb | Min | Max | Remarks | |

| CR-1 | 144.66 | 144.83 | 144.77 | 144.82 | 144.69 | 144.82 | 144.66 | 144.83 | Ovality – 0.17 MM |

| CR-2 | 144.64 | 144.77 | 144.79 | 144.81 | 144.65 | 144.73 | 144.64 | 144.81 | Ovality – 0.17 MM |

| CR-3 | 144.69 | 144.76 | 144.76 | 144.83 | 144.64 | 144.81 | 144.64 | 144.83 | Ovality – 0.19 MM |

| CR-4 | 144.61 | 144.74 | 144.74 | 144.79 | 144.68 | 144.75 | 144.61 | 144.79 | Ovality – 0.18 MM |

| CR-5 | 144.66 | 144.81 | 144.77 | 144.84 | 144.71 | 144.73 | 144.66 | 144.84 | Ovality – 0.18 MM |

| CR-6 | 144.67 | 144.85 | 144.78 | 144.80 | 144.72 | 144.77 | 144.67 | 144.85 | Ovality – 0.18 MM |

- On going through the above dimensions, it was noticed all 6 crank pins had ovality between 0.17 mm to 0.18 mm and were considerable down in comparison to standard diameter of 145.00 mm.

- The hardness of crank pins was checked with a portable hardness tester and was observed within limits.

- The MPI was conducted by our level 2 qualified technician.

- Multiple hairline cracks were observed on crank pin no.4 having a length ranging from 6 mm to 25 mm.

REPAIRS UNDERTAKEN BY RA POWER SOLUTIONS:-

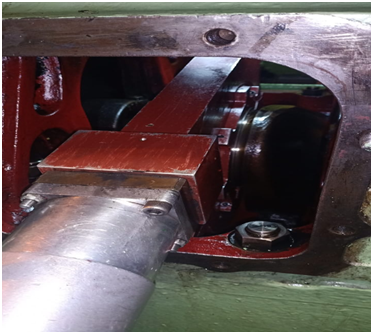

- Considering the ovality , multiple cracks on crank pin nos 4 and rough surface observed of YANMAR 6N18AL-DV.

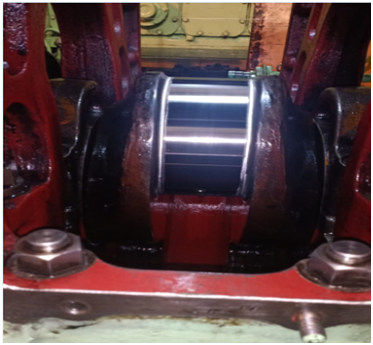

- All the six crankpins except crankpin no. 4 were undersized to 0.80 mm. The crank pin no. 4 has to be undersized by 1.20 mm due to the presence of cracks.

THE FINAL DIMENSIONS MAINTAINED AFTER GRINDING OF CRANK PINS IS MENTIONED BELOW:-

STANDARD DIMENSION: 145.00 mm

STANDARD /SPECIFIED NO

SIZE OF CR PINS

| A | Aa | C | Cc | B | Bb | Min | Max | Remarks | |

| CR-1 | 144.19 | 144.20 | 144.18 | 144.18 | 144.19 | 144.20 | 144.18 | 144.20 | Ovality – 0.02 MM |

| CR-2 | 144.20 | 144.19 | 144.19 | 144.18 | 144.20 | 144.19 | 144.18 | 144.20 | Ovality – 0.02 MM |

| CR-3 | 144.20 | 144.18 | 144.19 | 144.19 | 144.20 | 144.18 | 144.18 | 144.20 | Ovality – 0.02 MM |

| CR-4 | 143.80 | 143.80 | 143.79 | 143.78 | 143.80 | 143.79 | 143.78 | 143.80 | Ovality – 0.02 MM |

| CR-5 | 144.20 | 144.20 | 144.19 | 144.18 | 144.20 | 144.19 | 144.18 | 144.20 | Ovality – 0.02 MM |

| CR-6 | 144.20 | 144.19 | 144.18 | 144.18 | 144.20 | 144.20 | 144.18 | 144.20 | Ovality – 0.02 MM |

SUPPLY OF UNDERSIZE BEARINGS OF YANMAR 6N18AL-DV BY RA POWER SOLUTIONS:-

- The 0.80 mm and 1.20 mm under-size bearings were supplied by RA Power Solutions in a very short time and engine was put back into operation.

- We maintain a large stock of spare parts of YANMAR 6N18AL-DV or arrange through our principals on short notice.

THE MAIN FEATURES OF REPAIR OF CRANKSHAFT OF YANMAR 6N18AL-DV:-

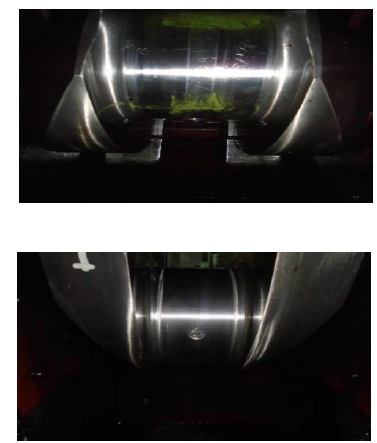

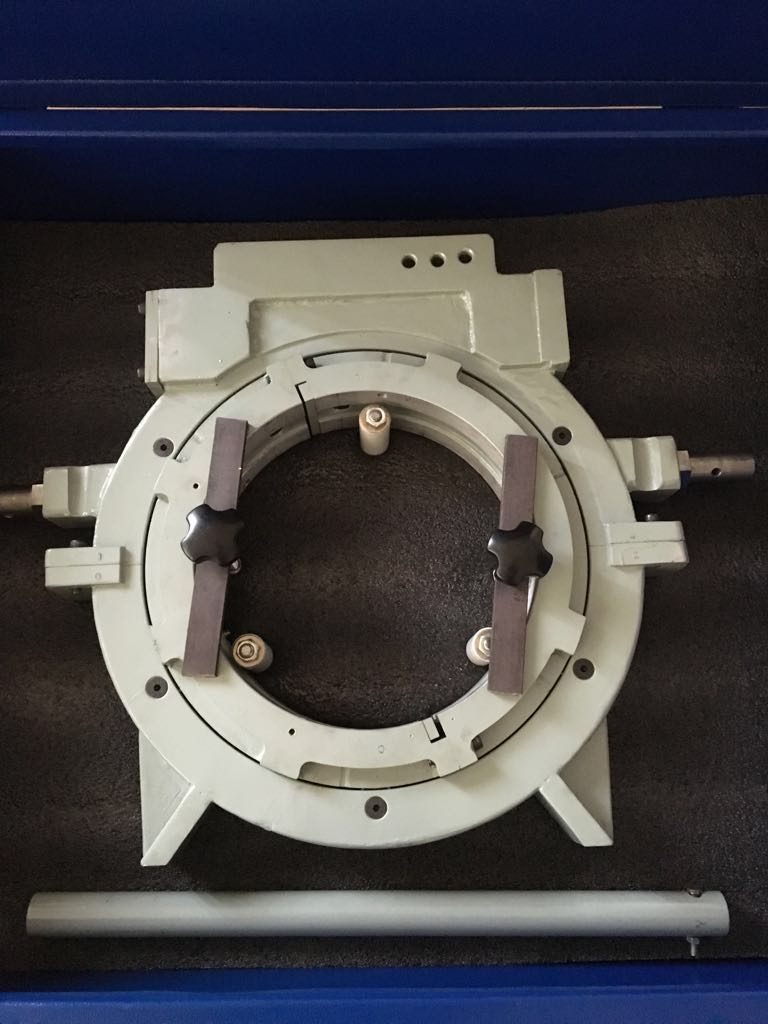

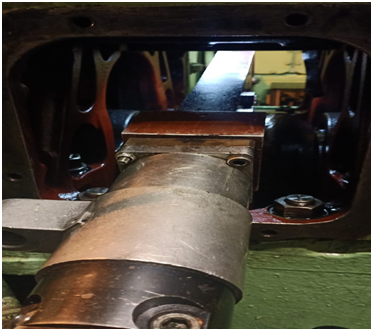

The crankpin having a diameter of 145 mm and a bearing length of only 65 mm was successfully repaired by us because of the fact, we have a dedicated crankshaft grinding machine which can undertake the grinding of crank pin having a small diameters and bearing widths.

Most of the companies based in Europe and other countries do not have the equipment which can on-site grind the crank pin and main journal diameter having a small diameter and bearing width. They advise clients to open the crankshaft from engine and send it to the workshop for repairs.

We extend our services all over the world at a very low price.

MAK , B&W , Sulzer , Bergen , Detroit Diesel ,Stork Werkspoor , Pielstick , Deutz , Yanmar , MTU , Cummins , Nohab Polar , Caterpillar , Mitsubishi , Yanmar , MAK and many more.

We have been regularly executing the repairs in Armenia, Azerbaijan, Bahrain, Bangladesh, Bhutan, Brunei, Cambodia, China, Cyprus, Georgia, Indonesia, Iran, Iraq, Israel, Japan, Jordan, Kazakhstan, Kuwait, Kyrgyzstan, etc.

This blog is written by Mr. Raj Shahani (Managing Director of RA Power Solutions India Pvt. Ltd.).

Mr. Shahani is a highly experienced business leader with rich experience of more than 40 years in the field of Power, Heavy and Shipping industries. He is Technical Adviser to many shipping and heavy industries across the globe.

Mr. Shahani is one of the most enthusiastic professional and he has all the brilliance of an exemplary leader. Mr. Shahani is an extremely effective coach and mentor of teams and is adept at providing leadership in a global, cross-cultural environment.

For more information on crankshaft repair, crankpin repair, and yanmar engine repair contact us at rajshahani@rapowersolutions.com or info@rapowersolutions.com or call us at +91 9582647131 or +91 9810012383.