Crankshaft is the heart of every engine. It is estimated that the cost of crankshaft is almost 30 to 35% of the total cost of engine. RA Power Solutions considers and treats every crankshaft with the greatest attention. The inexpertly ground crankshaft can lead to the failure of bearing and crankshaft in totality causing considerable damage and loses to the owners.

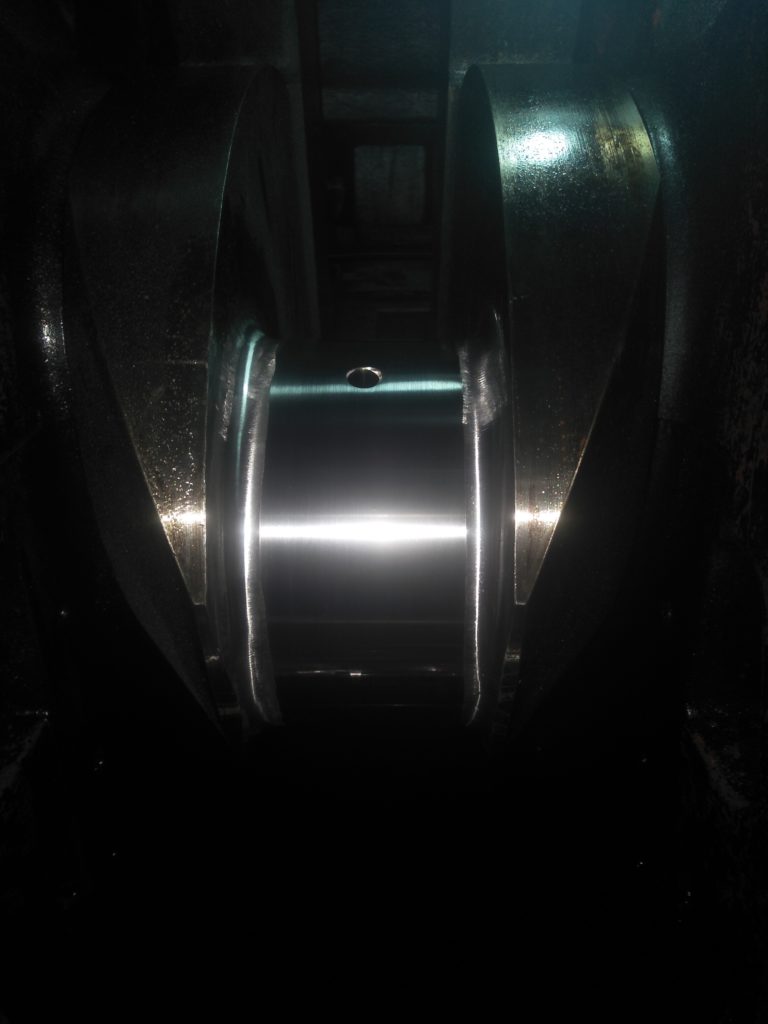

RA Power Solutions undertakes onsite crankpin grinding and crankpin polishing in one setting. The portable, light weight onsite crankshaft grinding machine is taken to the site. The crankshaft grinding machine is designed in such a way that it can undertake the crankshaft machining, crankshaft grinding and crankshaft polishing in one setting.

The forty-three years of experience of our company and staff guarantees machining, grinding, and polishing of crankshaft to the highest professional standards strictly in accordance to the tolerances stipulated by the manufacturers. Our experience of working on crankshaft and the trust of our clients have resulted to successfully repair of more than 10,000 crankshafts Worldwide.

The services of crankshaft grinding and crankshaft polishing are extended for all the applications including forging hammers, marine and industrial.Our location in India gives us an opportunity to serve our clients in Middle East Asia and European countries.

Technician’s having Indian CDC can sail on the vessel and can execute the repairs. The main advantage of availing RA Power Solutions services is not only limited to the availability of experienced technicians but all the repairs like metal stitching, repair of major parts, dismantling and overhauling of DG sets is also offered.

We stand guarantee for all the jobs executed by us for successful repair of the engine in totality.

For more information on crankpin grinding and repair, grinding of crankpin, crankshaft grinding repair services, insitu crankpin grinding, or crankshaft polishing please email us at rajshahani@rapowersolutions.com, or info@rapowersolutions.com, or call us at +91 9582647131 or +91 9810012383.