Cast iron crack repair by metal stitching and metal locking process is highly recommended. Metal stitching process for repairing casting is widely use, and accepted in the industry, and more successful process for repairing cracks in cast iron.

Steam turbine casing of Hangzhou make was reported damaged due to accident. The turbine operates at 130 MW peak load.

RA Power Solutions deputed technician to the site with latest breed of instruments, equipments and consumables in order to undertake inspection of the turbine casing and to execute necessary repair following observation was made.

Observation-

Turbine casing due to accident developed multiple cracks at different locations. Crack of following dimensions were observed

- Crack having a length of 190mm with indiscipline profile

- 2 Cracks having length of about 300mm

- Casting having dimensions of 600mm/450mm with thickness of 45mm was damaged into pieces

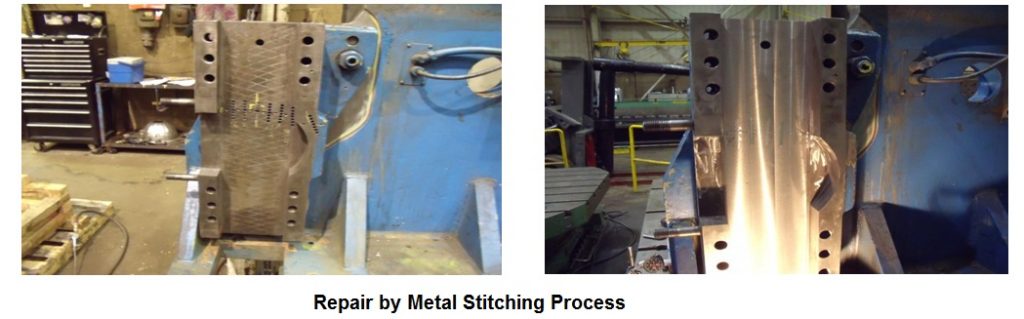

Crack repair by Metal lock and Metal stitching.

Crack Repair and damaged casting replacement was undertaken by RA power technicians.

- The damaged casting area was cut and disciplined profile was given measuring 650mm/520mm this area was properly ground

- The damaged sample piece was sent for metallurgical test to know the composition of material.

- A wooden pattern was made at site having an exact profile as of damaged area.

- A new casting piece having superior metallurgical properties then the original damage casting was manufactured.

- The new casting piece was fixed in damage area by metal stitching and metal locking process.

- RA power engineers used metal locks, metal keys and all consumables’ imported from UK for repair of cracks and damage casting.

- The polishing of outer and inner surface of damaged area was done and painted.

- The turbine is presently working satisfactory and has completed 3500hr of operation.

RA power under takes repair of crack casting by metal stitching and metal locking process from last 40 years and have executed successfully repair of heavy components used in power plants, industry, ships etc…

The metal stitching and metal locking can also be undertaken while sailing the vessel.

To know more about cast iron crack repair, metal locking, cast iron stitching, metal surgery, and engine block repair, please email us at rajshahani@rapowersolutions.com, or info@rapowersolutions.com, or call us at +91 9582647131 or +91 9810012383.