When a metal component cracks—especially in large equipment like engine blocks, compressors, or turbines—repair options can be costly, time-consuming, and risky if not done correctly. One highly effective method that avoids heat, preserves alignment, and restores structural integrity is metal stitching, also known as metal locking.

Understanding Metal Stitching

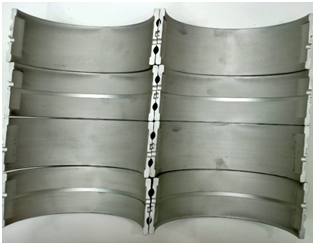

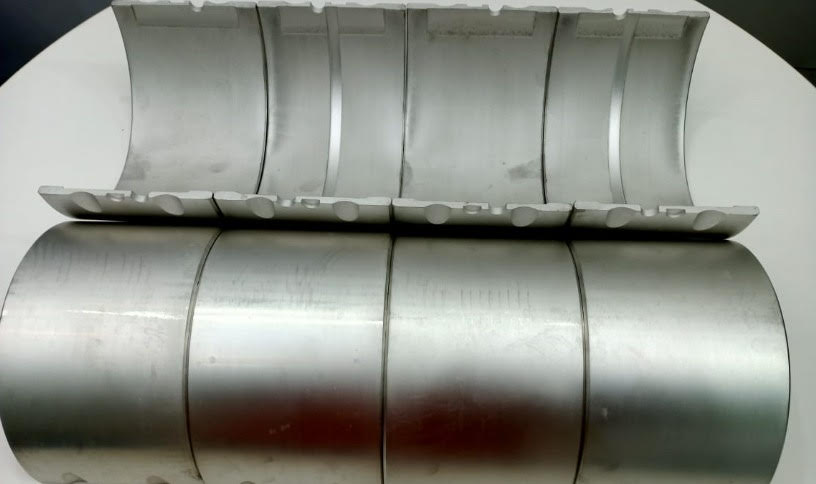

Metal stitching is a cold mechanical repair process used to fix cracks or breaks in cast metals such as cast iron, aluminum, steel, and bronze. Unlike welding, which uses high heat, metal stitching relies on precision-drilled holes, specially designed stitching pins a nd locks to seal and reinforce the damaged area.

This technique is ideal for industrial applications where heat could distort components or where disassembly isn’t feasible.

How the Process Works

Here’s a simplified breakdown of how metal stitching is done:

- Crack Detection: Identify and inspect the full extent of the crack.

- Drilling Pattern: A series of holes is drilled along and across the crack.

- Slot Cutting: A slot is formed to fit stitching locks or keys.

- Installing Locks: Metal locks are inserted into the slots to mechanically bind both sides of the crack.

- Threaded Studs: In some cases, overlapping threaded studs are used to seal the crack.

- Sealing & Finishing: The surface is peened and machined smooth to match the surrounding area.

Why RA PowerSolutions?

At RA PowerSolutions, we specialize in on site metal stitching and metal locking for all types of cast components. There is no need for dismantling or transporting the part.

With decades of experience and hundreds of successful global repairs. We help industries reduce downtime, avoid expensive replacements, and restore strength and performance efficiently.

Our services include:

- Metal stitching of engine blocks, compressors, pumps, etc.

- On site machining and grinding

- Repair of crack-prone components like turbine casings and gearbox housings

- ISO-certified technicians and portable tools

If you’re facing a critical breakdown or seeking long-term solutions for metal cracks, RA PowerSolutions is ready to assist with expert, onsite support. Contact us today to learn more or schedule an inspection.

For more details on the Metal Stitching and Metal Locking , Crack Repair by Metal Stitchng email us at info@rapowersolutions.com. Call at +91-9582647131,+91 9810012383.

FAQs:

Metal locking crack repair process – Metal-lock or metal stitching is a method of repairing fractures to castings, onsite without the use of heat. It involves sinking Metal-lock keys, perpendicular to a fracture. The fracture is then sealed and held rigid by Metal-lace studs

Metal stitching does not use heat, so there’s no distortion or weakening of the material. It preserves the original shape and alignment of the part and is ideal for cast iron, which is prone to cracking when welded.

Yes, RA Power Solutions specializes in on site metal stitching, allowing us to repair damaged equipment without dismantling or transporting it—saving time, cost, and downtime.