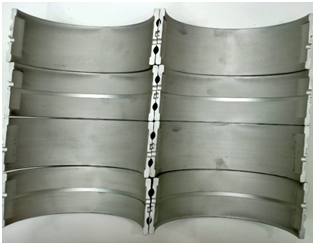

We are the leading manufacturer and supplier of Tri metal bearing, Engine tri metal bearing, crank pin bearing, main journal bearing and Bi metal Bearing, and Engine bearing for all types of Rotating equipment.

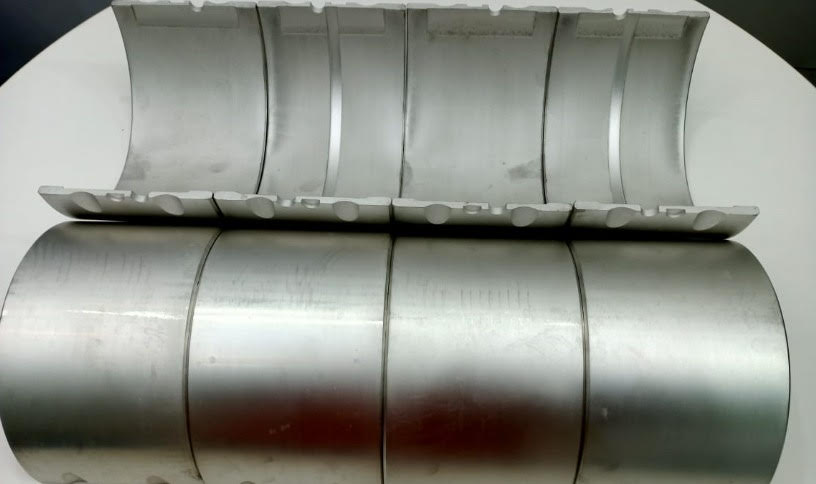

The Bi metal Bearings up to 1500 mm diameter are manufactured by centrifugal process and Tri metal bearings are sourced from our Principles based in UK, Germany, and Japan.

Our specialization in Tri Metal Bearing for crank pin/ main journal of marine engine

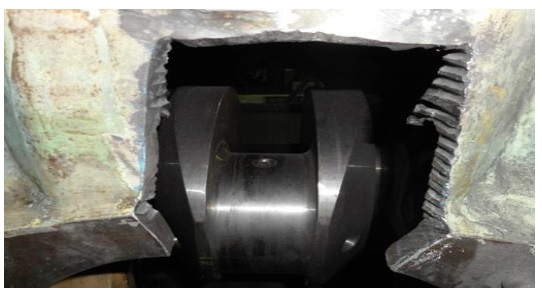

RA Power is engaged in extending on site crankshaft repair services all over the world for the last more than 41 years.

It is obvious that whenever the grinding of the crank pin & main journal of the diesel engine or compressor crankshaft is undertaken there is a requirement for under size crank pin and main journal bearing.

It is generally observed that in most cases it is difficult to source under-size bearings from the manufacturer of the engine and compressors as they are not available in the stock. The problem arises when there is a requirement for a special size undersize of the bearing.

We have also observed that in the case of an engine make & model which is more than 15 years old it is rather impossible to source the bearing from the manufacturer of the engine as that particular model is discontinued by the manufacturer.

The ship owners or the customers having old models of engines face this problem of nonavailability of crank pin and main journal bearing.

RA Power Solutions plays an important role in arranging the special & under-size bearing according to the dimensions of the crank pin and main journal obtained after grinding.

Development & manufacturing of Tri metal & Bi metal Bearing for crankpin and main journal of the crankshaft

We specialize in the development and manufacturing of under-size-bearing of old and absolute models of engine production which is discontinued by the engine manufacturer.

We manufacture the bearings as per the drawing & technical data available with us or alternatively Tri metal bearings are manufactured by us as per the sample provided by the client.

Our acceptance of a small quantity of undersize and special size bearing of crank pin and the main journal is of great assistance to our client.

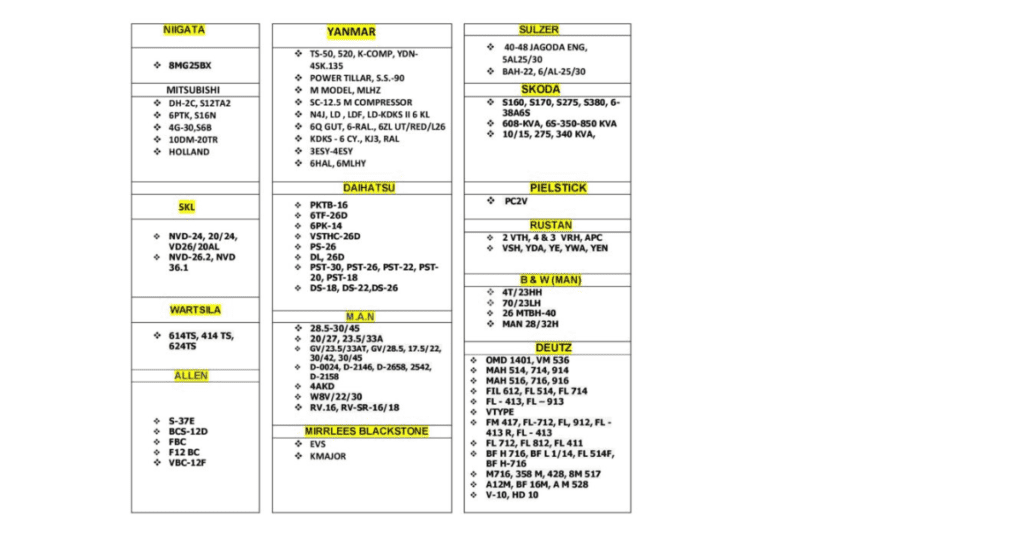

We manufacture & supply bearings for all makes & models of marine engines & auxiliary engines which include the following:

This blog is written by Mr. Raj Shahani (Managing Director of RA Power Solutions India Pvt. Ltd.).

Mr. Shahani is a highly experienced business leader with experience of more than 40 years in the field of Power, Heavy, and Shipping industry. He is Technical Adviser to many shipping and heavy industries across the globe.

For more information on bearing manufacturing company, white metal bearing alloy ingot, or Engine bearing contact us at rajshahani@rapowersolutions.com or info@rapowersolutions.com or call us at +91 9582647131 or +91 9810012383.