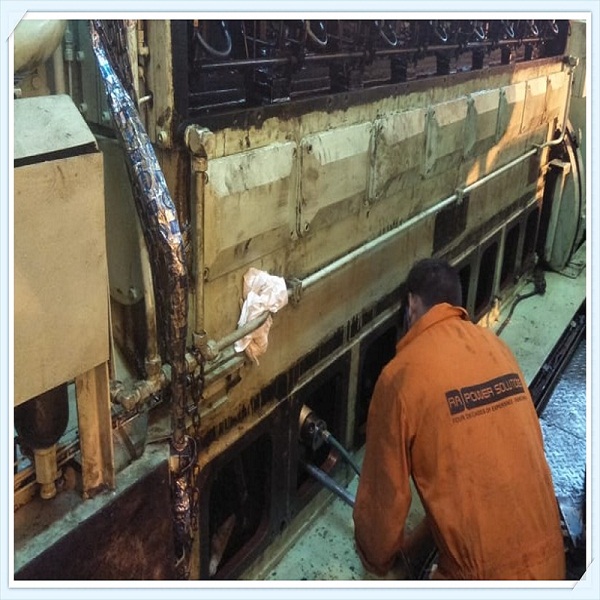

RA Power Solutions is the leading company extending Diesel Engine maintenance, Repair & overhaul services having experience of 40 years in this field. We have a team of skilled technicians & engineers who have worked in shipyards, Diesel Power Plants & Engine manufacturing companies. RA Power Solutions feel that proper analysis of trouble in Diesel Engine & its solution is of great importance for successful repair. Our technicians are able to quickly analysis in the case of breakdown & undertake the corrective action.

The major overhaul of MAK M453C main engine undertaken by our engineers recently was executed in record time & detail scope of work is as following:

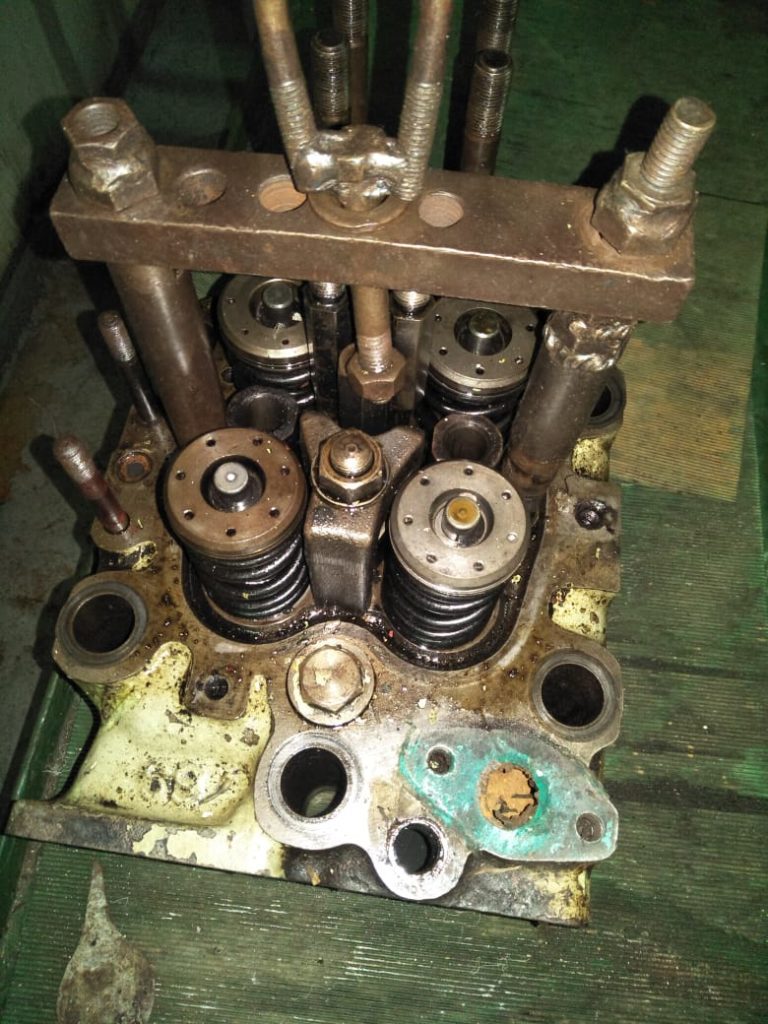

- Overhaul of 6 nos cylinder head, replacement of valve seats and valve guides. Replacement of all valve stem guide O-ring seals. Checked cylinder heads warpage and pressure testing of all heads at 5 bar.

- Overhaul of jacket water, lubricating oil cooler and charged air coolers.

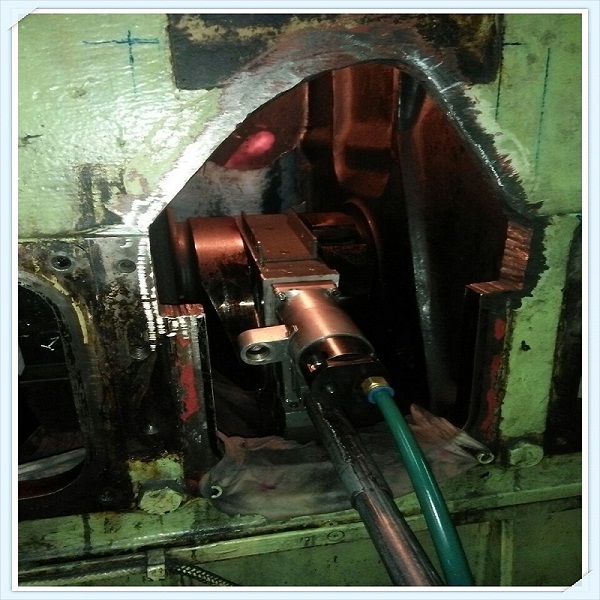

- Dismount and overhaul of VTR 250 turbocharger, renewed the oil slinger, nozzle assembly, and both compressor and turbine side bearings.

- Dismount and overhaul of all the air starting valves, relief valves, the piston rings, and seals were changed.

- Withdraw all the pistons, cleaned piston ring landing and renewal of piston rings gudgeon pins, and big end bearings.

- Took piston ring groove axial and butt clearances.

- Clean inspect and measure the cylinder liner internal diameters.

- Deglaze the cylinder liners with 120 grit emery cloth.

- Measurements of bearing cap gaps (k1-k2).

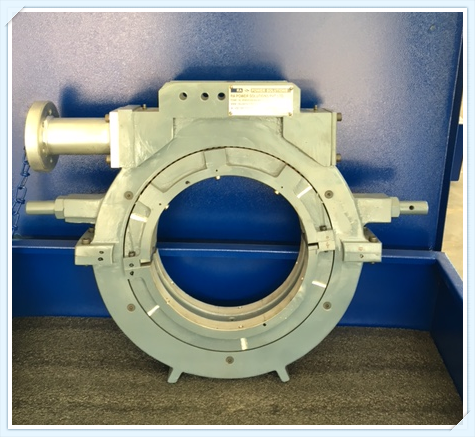

- Polished the crankshaft and took journal measurements.

- Renewed all main and locating bearing shells.

- Took main bearing top clearances by lead wire.

- Took crank web deflection measurements prior and after the renewal of main bearings with spring loaded dial gauge.

- Took measurements of both normal and locating bearings k-gap.

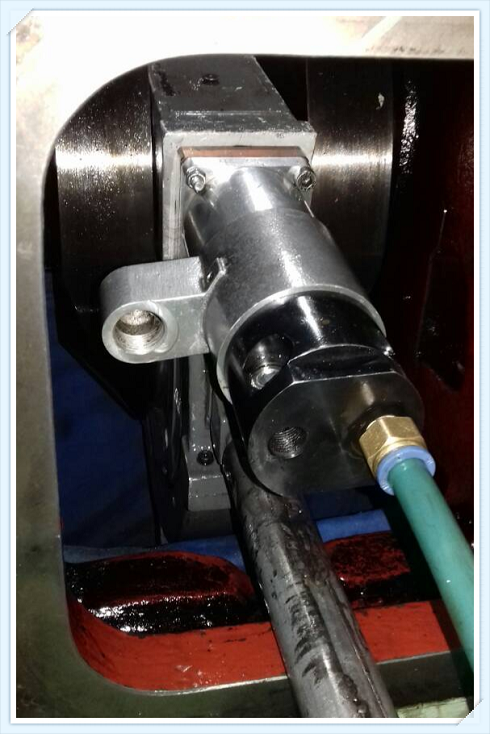

- Dismount and overhaul all fuel injectors and pressure tested the nozzles.

- Dismount and overhaul the fuel pumps and replace the springs, delivery valves, plungers, and barrels.

- Setting of valves tappet clearances.

- Overhauled both emergency and attached lubricating oil pumps.

- Dismount and overhaul of the jacket water pump replaced the bearing and mechanical seal.

The author is Mr. Raj Shahani, Managing Director of RA Power Solutions Pvt. Ltd. He has 40 years of experience in working on large crankshafts and Diesel Engines. He is on the board of directors of reputed shipping companies and companies having a large number of Diesel power plants.

For your requirement of diesel engine overhaul and repair, large diesel engine repair, overhauling of diesel engine, overhauling & repair of marine engine please email us at rajshahani@rapowersolutions.com, or info@rapowersolutions.com, or call us at +91 9582647131 or +91 9810012383.