Contact RA Power Solutions for undertaking the crankshaft grinding of Daihatsu 5DC-17 and all models without removing the crankshaft from the block.

MAJOR TECHNICAL DETAILS OF DAIHATSU DC-17 :

| S. NO | Crankshaft Details | |

| 1 | Engine Make | Daihatsu |

| 2 | Engine Model | 6DC-17 Engine |

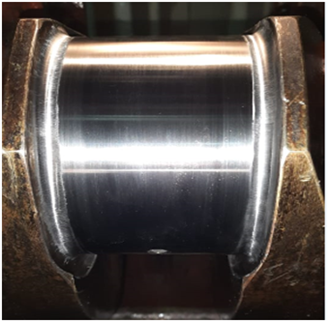

| 3 | Crankpin Diameter Standard | 145mm |

| 4 | Crankpin Bearing Width | 64mm |

| 5 | Place of execution of crankshaft repair | Odisha Port India |

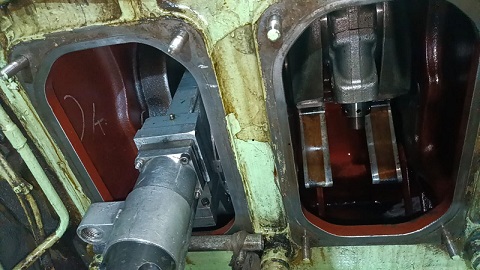

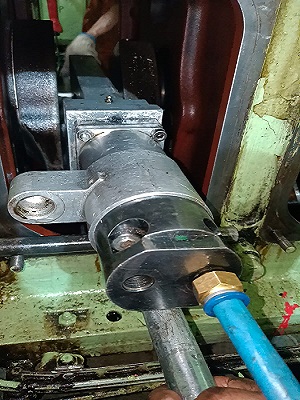

As can be seen from the above the crankshaft of Daihatsu DC 17 crankpin width is only 64 mm and diameter is 145 mm which is considered to be very small. It requires a very compact design of Insitu crankshaft grinding machine which can be inserted from the engine block.

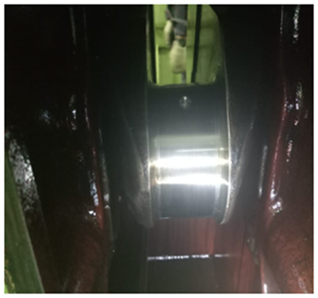

RA Power Solutions is the only company in the world which has the latest technology, Equipment, and process available for crank pin grinding and polishing of Daihatsu DC-17 without removing it from the engine block. The grinding of crankpin can also be done while sailing of the vessel.

Save Crankshaft of Daihatsu DC-17 contact RA Power Solutions for successful and Guaranteed repair

- Since no other crankshaft repair company in the world has equipment, technology, and process available for repair of the crankshaft of Daihatsu DC17, they insist on removing it from the block and sending it to the workshop or rejecting it by giving some excuses.

- Contact RA Power Solutions who have more than forty-three years of experience in onsite crankshaft grinding and have successfully repaired more than hundred crankshafts of Daihatsu DC-17 all over the world.

- The reference of that client, certificate of satisfactory performance, and inspection reports signed by chief engineers of the vessel can be furnished on request.

- Reduce downtime, and save crankshaft by getting it repaired by RA Power Solutions.

- Undersize bearings of all sizes of crank pin are available in our stock.

RA Power Solutions is ISO 9001:2015 (Quality Management System) & ISO 14001:2015 (Environmental Management System) certified approved company.

We have been regularly executing on-site crankshaft repairs and crankshaft grinding in Dubai, Oman, Saudi Arabia, Qatar, Abu Dhabi, Sharjah, Ajman, Umm Al-Quwain, and Fujairah, Bahrain, Kuwait, Iraq, Antigua and Barbuda, Belize, Dominica, Dominican Republic, Grenada, Guyana, Haiti, Jamaica, Saint Kitts and Nevis, Saint Lucia, Saint Vincent and the Grenadines, Trinidad, and Tobago, etc.

For more details on the Repair of engine please email us at raj.shahani@rapowersolutions.com, info@rapowersolutions.com or Call +91-9582647131,+91 9810012383.