CKD Skoda engines and CKD Skoda diesel generating sets are slow RPM and are installed all over the world. Presently, CKD Skoda plant is closed for last 15 years and due to non availability of spares various problems are faced by the clients having CKD Skoda generating sets or CKD Skoda engines installed for applications like shipping and industries.

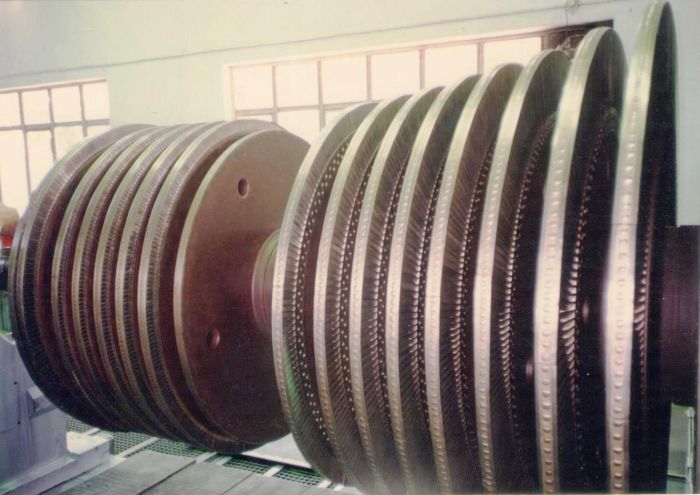

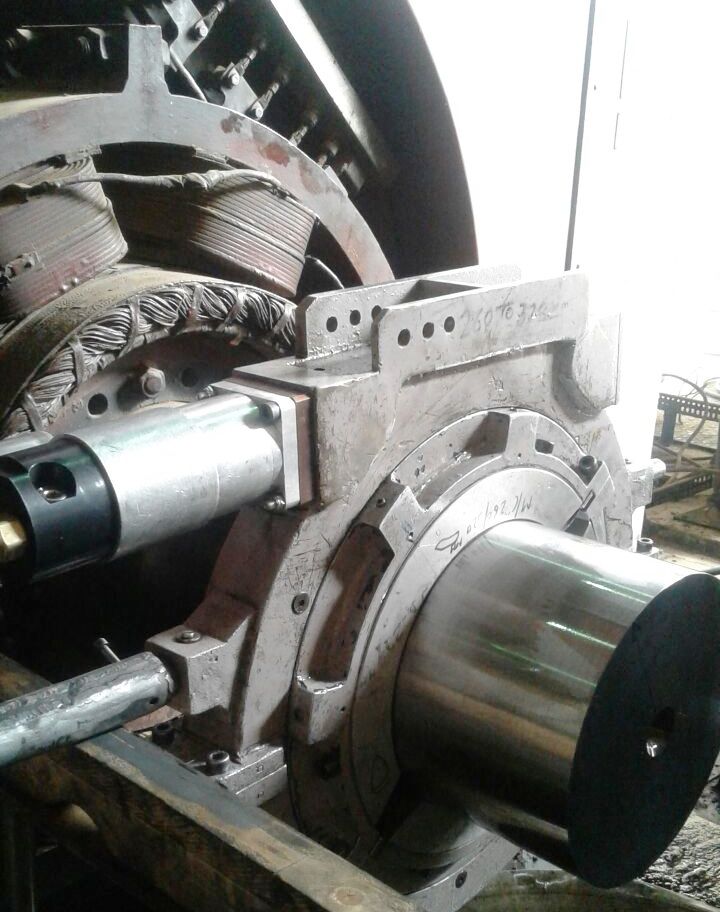

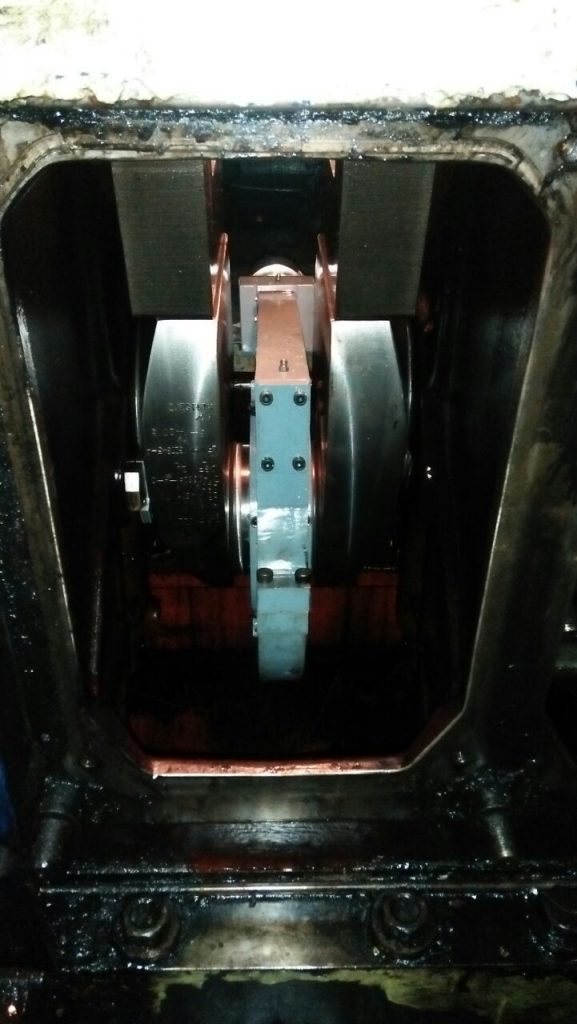

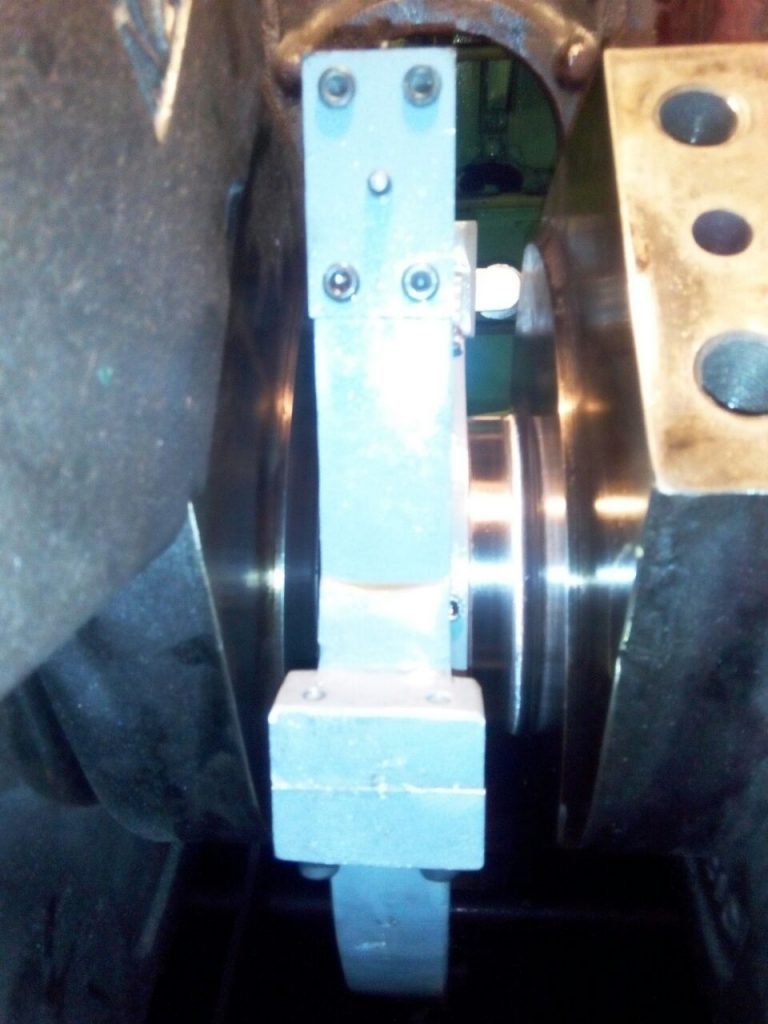

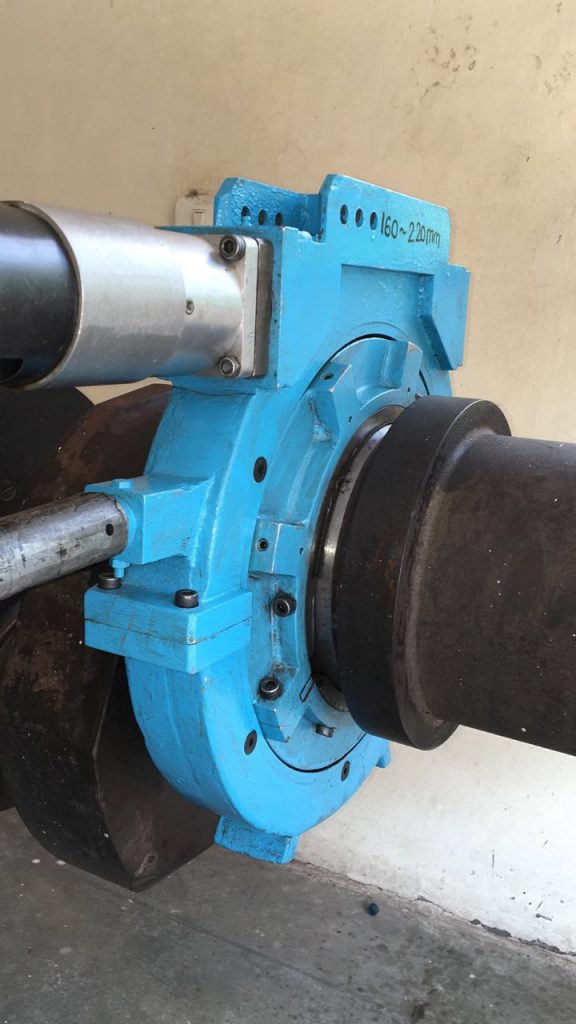

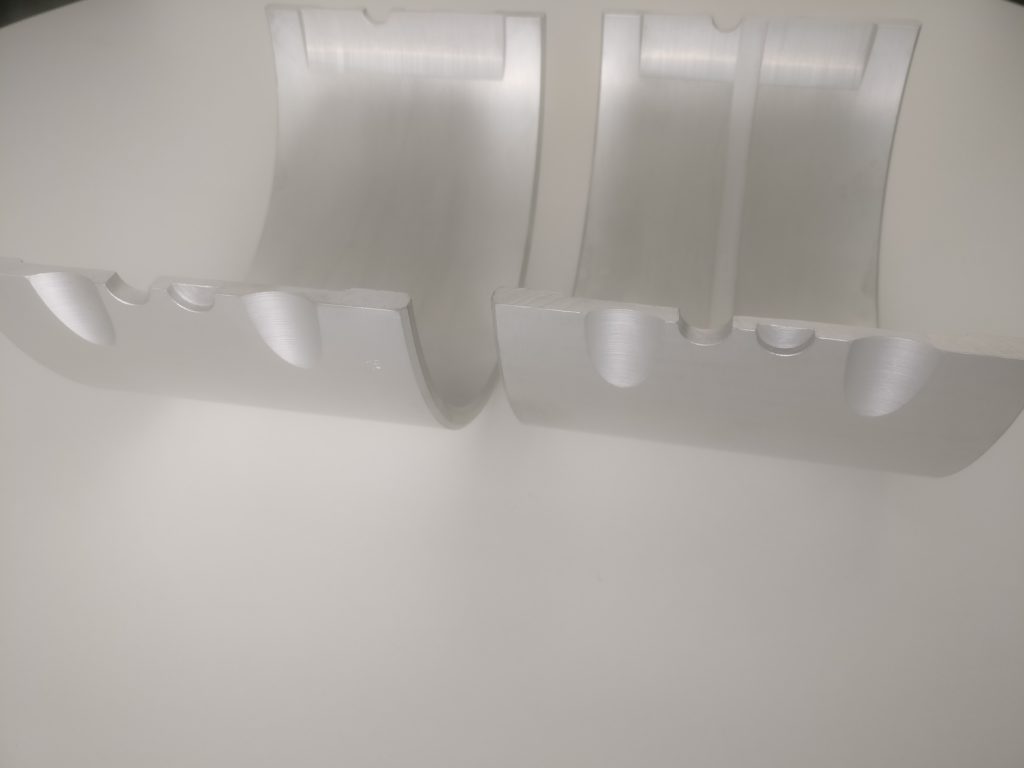

RA Power Solutions is associated with CKD Skoda since 1982 . We manufacture and supply Skoda white metal bearing and Skoda tri metal bearings for crankpin and main journals. The CKD Skoda bearings are manufactured under the strict quality norms. We have been regularly exporting these bearings all over the world including Czech Republic. A country where CKD Skoda IV) engines were manufactured.

Parts like Crankshaft, cylinder liners, valves, etc for CKD Skoda engines are available.

We have ready stock for following Skoda engines:

- CKD Skoda 500 KVA

- CKD Skoda 608 KVA

- CKD Skoda 860 KVA

- CKD Skoda 1450 KVA

- CKD Skoda 2270 KVA

We maintain inventory for following models of CKD Skoda Diesel Generating Sets:

| OUTPUT (kVA) | FREQUNCY (Hz) | VOLTAGE (V) | DIESEL ENGINE | RPM |

| 405 | 50 | 400/231 | 6S275III | 600 |

| 405 | 50 | 400/231 | 6-27,5 A0S | 600 |

| 500 | 50 | 400/231 | 6S275PN | 500 |

| 608 | 50 | 400/231 | 6S275IIIPN | 600 |

| 608 | 50 | 400/231 | 6-27,5 A2S | 600 |

| 825 | 50 | 400/231 | 6S275IIIPV | 600 |

| 825 | 50 | 400/231 | 6-27,5 A4S | 600 |

| 860 | 50 | 400/231 | 6S350PN | 375 |

| 860 | 50 | 6300 | 6S350PN | 375 |

| 860 | 50 | 11000 | 6S350PN | 375 |

| 1525 | 50 | 6300 | 9S350IIPS | 375 |

| 1525 | 50 | 11000 | 9S350IIPS | 375 |

| 1525 | 50 | 6300 | 9TS35/50-2 | 375 |

| 1525 | 50 | 11000 | 9TS35/50-2 | 375 |

| 1600 | 50 | 400/231 | 6-27,5 B8S | 750 |

| 1600 | 50 | 6300 | 6-27,5 B8S | 750 |

| 1600 | 50 | 11000 | 6-27,5 B8S | 750 |

| 2140 | 50 | 6300 | 6-27,5 B8S | 750 |

| 2140 | 50 | 11000 | 6-27,5 B8S | 750 |

| 2270 | 50 | 6300 | 6-38 A6S | 500 |

| 2270 | 50 | 11000 | 6-38 A6S | 500 |

For more details regarding CKD SKODA Bearings please email us at rajshahani@rapowersolutions.com, or info@rapowersolutions.com, or call us at +91 9582647131 or +91 9810012383.