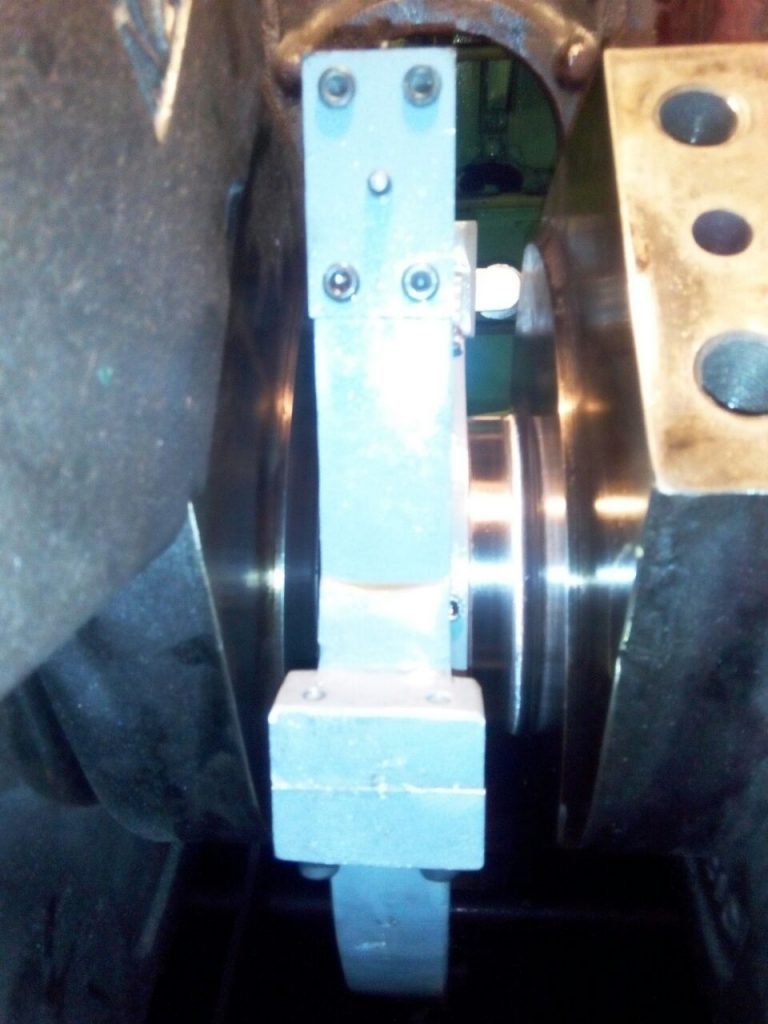

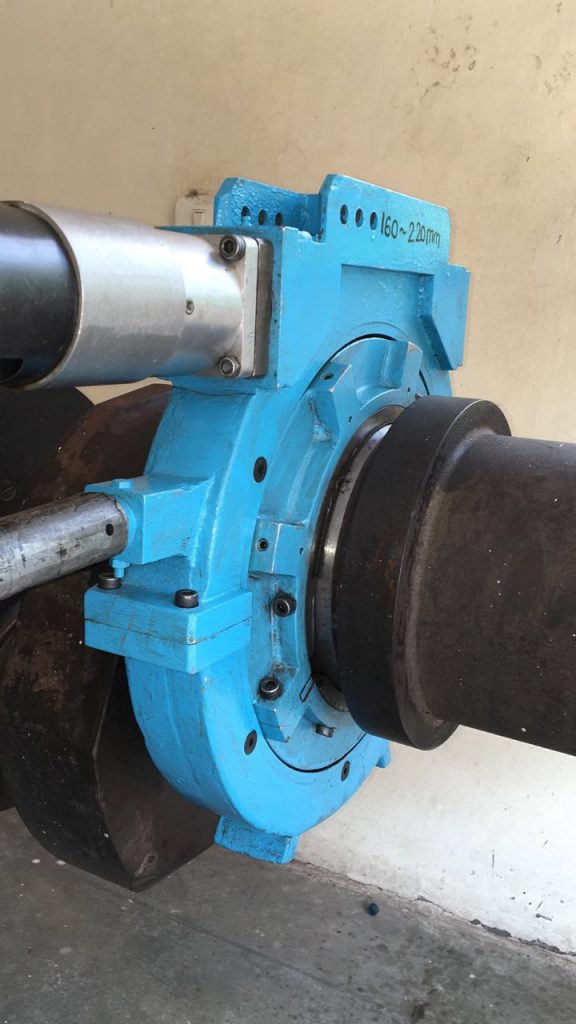

RA Power Solutions has four decades of experience undertaking grinding and polishing of crankshaft. We can undertake onsite grinding and polishing of crankshaft from 50 mm to 700 mm. Team of experienced technicians are deputed to the site with lightweight, portable crankshaft grinding machine. The repair of crankshaft is done without removing the crankshaft from the engine block. This saves time and cost involved in disassembly of crankshaft, packing, and transportation of crankshaft to the workshop.

Worldwide the repair of crankshaft in workshop is outdated. We depute our technicians all over the world with portable equipments for repair of crankshafts. The repair is executed strictly as per the manufacturer’s specifications and tolerances. The crankshaft repairs are guaranteed for satisfactory performance.

The recent introduction of vibration-less portable onsite crankshaft grinding machine facilitates us to execute crankshaft repair while vessel is sailing.

Our technicians have seaman passports and they can board the vessel from one port and disembark from another port. Thus, saving the cost of anchorage or stay at port.

We also manufacture crankshaft grinders which are priced low and easy to operate. These revolutionary machines are recommended for shipping companies, repair workshop heavy engineering company, etc.

For more information, call us at +91 – 124 – 4378292, +91 9582647131, or email us at rajshahani@rapowersolutions.com, info@rapowersolutions.com.