MAN Diesel Engine 9L28-32

RA Power Solutions was approached by a company based in Dubai regarding a problem in crankshaft faced in MAN Diesel Generating set model no. 9L28/32.

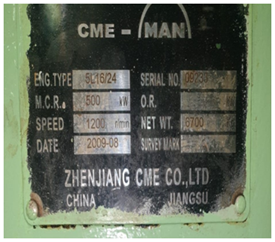

The make, model of Engine, and crankshaft details are given below:

| S. NO | Crankshaft Details | |

| 1. | Engine Make | MAN B&W |

| 2. | Engine Model | 9L28/32 |

| 3. | Crank pin Diameter Standard | 230 mm |

| 4. | Crankpin Bearing Width | 98 mm |

| 5. | Place of execution of crankshaft repair | Sailing from Port of Jebel Ali Dubai to JNPT port India(Mumbai) |

Repair of MAN Engine Model no. 9L28/32 Diesel Generating set Crankshaft

RA Power Solutions deputed two technicians along with an onsite crankshaft grinding machine and technicians boarded the vessel at port of Jebel Ali Dubai. On conducting the inspection following are the main observations of the crankshaft of MAN Engine Model no. 9L28/32 diesel Generating sets.

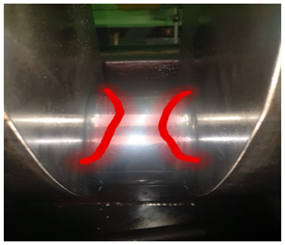

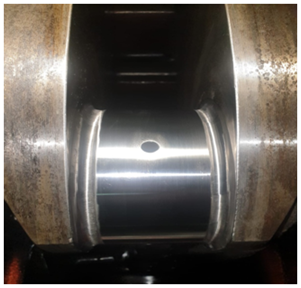

- It was observed that the crankpin no. 3 of the AE#02 was damaged. The Bearing material was embedded on the crank pin diameter. After removal of the white metal from the crankpin, the dimension inspection was done and the following was observed:

- Minimum crankpin diameter observed: 229.44 mm

- Maximum crankpin diameter observed: 229.83 mm

- The above readings were observed against the standard diameter of 230.00 mm.

- The radius fillet and lubricating oil hole profiles were found acceptable with no damage.

- Deep Bearings line marks were observed on the remaining 8 numbers of crankpins.

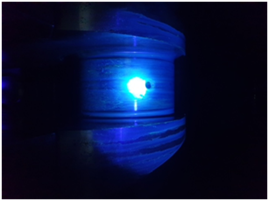

- All the crankpins were subject to hardness test and crack check by MPI method and no abnormality was observed.

- All other parameters were observed within limits.

Successful Crankshaft Repair of MAN Engine Model no. 9L28/32

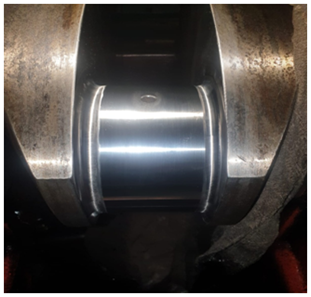

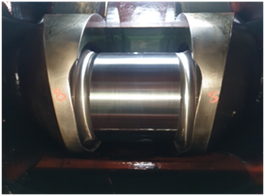

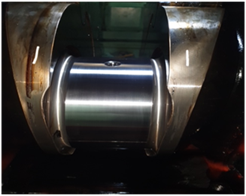

- The grinding of crankpin no. 3 was initially undertaken to the undersize of 1.0 mm maintaining the crankpin diameter of 229.00 mm. Since the Bearing line marks were still visible it was decided to grind further. The final size maintained after grinding and polishing was 228.50 mm which is 1.5 mm undersize.

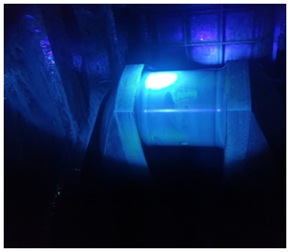

- Considering the rough surface finish and bearing line marks all the remaining crankpins were polished while using the state of art crankshaft grinding & polishing machine using the latest polishing media.

- The surface finish of less than 0.20 RA value was maintained.

- The ship had the 1.5 mm undersize bearing available which was assembled and the engine was put on load.

RA Power Solutions having more than 41 years of experience in extending crankshaft grinding, metal stitching, rebabbitting of bearing, and all the services related to engine repair. We undertake onsite grinding of crankshaft up to 700 mm diameter.

The main feature of our crankshaft grinding machine is that the grinding & polishing of the crankshaft can be undertaken even while sailing of the vessel. There is no requirement of holding the vessel at the port or at Anchorage.

For more details regarding crankshaft grinding, rebabbitting of bearing, and engine block repair, please email us at rajshahani@rapowersolutions.com, or info@rapowersolutions.com, or call us at +91 9582647131 or +91 9810012383.