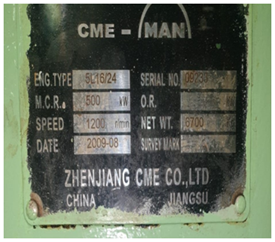

MAN Engine Model no. 5L 16/24 is a very common installation on vessels and the engine is used as Generator. The Crank Pin diameter of MAN Engine Model no. 5L 16/24 is only 130mm and the bearing width is 56 mm. In other words, it is about 2 inches

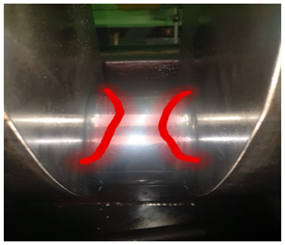

This makes the onsite crankshaft repair very difficult due to limited space in between the two webs. Most onsite crankshaft repair companies based in Europe don’t have the equipment and the technology to undertake grinding/ repair of crankpin of MAN Engine Model no 5L 16/24. The repair companies always suggest to remove it from the engine block and send it to workshop for crank pin grinding or reject the crankshaft.

We successfully executed the repair of the crankshaft of MAN Engine Model no. 5L 16/24. Details are as mentioned below:

| S. NO | Crankshaft Details | |

| 1 | Engine Make | MAN B&W |

| 2 | Engine Model | 5L 16/24 |

| 3 | Crank pin Diameter Standard | 130 mm |

| 4 | Crankpin Bearing Width | 56 mm |

| 5 | Place of execution of crankshaft repair | Port of Castellon Spain |

Details of Crankshaft repair job executed by RA Power Solutions technicians at a port of Castellon Spain.

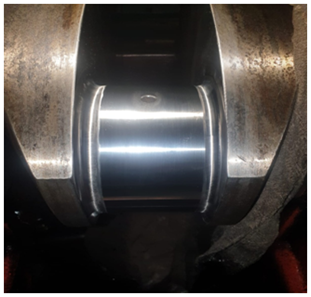

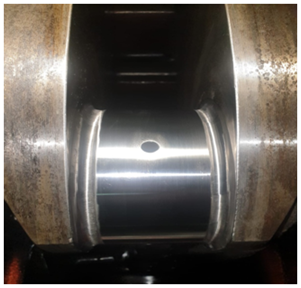

- The damaged crankpin was checked for taper & ovality and it was observed 0.49 mm.

- Deep bearing line marks were observed.

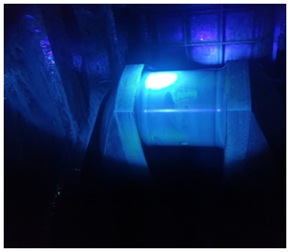

- All other parameters like hardness and crack detection by MPI were checked and no abnormality was found.

- The crankpin was ground to an undersize of 1.0mm.

Supply of Undersize Bearing for MAN Engine Model No. 5L 16/24

It is obvious that whenever grinding is undertaken there is requirement of undersize bearing. In this case of MAN Engine Model no. 5L 16/24, RA Power Solutions arranged and supplied 1.0 mm undersize crankpin bearing to the client.

We maintain a large stock of standard & undersize bearings of crankpin & main journal of popular make & model of engines like Yanmar, Daihatsu, MAK and MAN B&W, etc.

The Engine was commissioned in presence of our technicians and performance was found to be satisfactory.

For more details on the crank pin grinding machine please email us at info@rapowersolutions.com, or rajshahani@rapowersolutions.com, Call at +91 9582647131,+91 9810012383.