RA Power Solutions was approached by a leading shipping company regarding the problem faced by them in the crankshaft of Daihatsu 5DK-20 Auxiliary Engine.

The vessel was visiting Visakhapatnam port India and it was decided to undertake the repair of the damaged crankshaft in Visakhapatnam port.

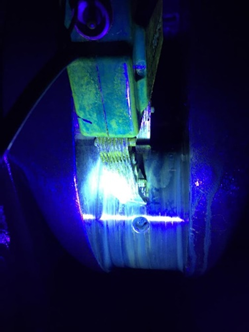

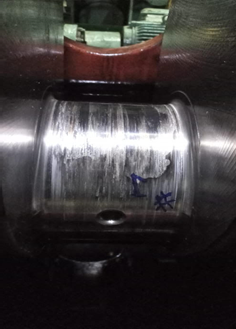

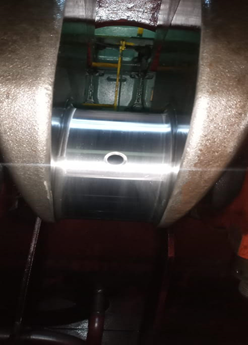

RA Power Solutions technicians undertook the grinding of four numbers of crankpins having a standard diameter of 170 mm. Due to serious damage to the crankpin, we have to undertake the grinding of two crankpins to the undersize of 0.5 mm, and on balance two crankpins were undersized by 1.0 mm. The job of crankpin repair of Daihatsu 5DK 20 Auxilary engine was undertaken in 76 hours without holding a vessel.

Supply of undersized bearing of Daihatsu 5DK-20 Engine crankshaft

We have supplied the undersize bearing of the crankpin to the client and the engine is performing satisfactory.

For more details of the crankpin grinding machine, crankpin polishing of daihatsu engine, daihatsu 5Dk-20 engine repair, bearing of Daihatsu 5DK-20 Engine crankshaft, or crankshaft grinding and repair email us at info@rapowersolutions.com, rajshahani@rapowersolutions.com, Call at +91 9582647131,+91 9810012383.