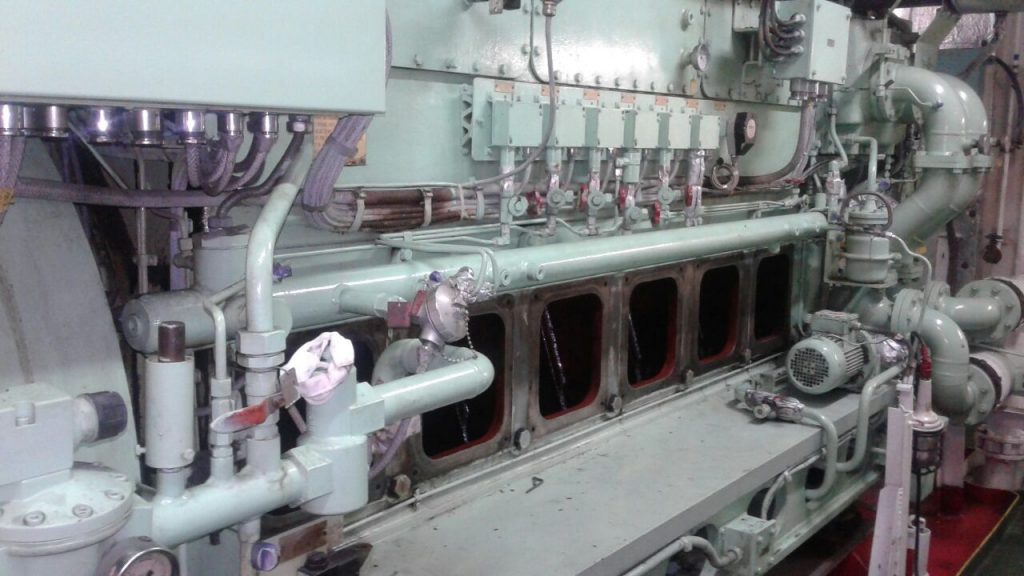

RA Power Solutions was approached by a company based in Greece regarding a problem faced by them in their auxiliary engine of Daihatsu 6 DK-20.

It was reported that the bearing of crankpin no.3 got damaged.

THE ENGINE DETAILS OF DAIHATSU 6 DK-20 ENGINE ARE AS FOLLOWS:-

| S. NO | Crankshaft Details | |

| 1 | Engine Make | Daihatsu |

| 2 | Engine Model | 6 DK-20 |

| 3 | Crankpin Diameter Standard | 170 mm |

| 4 | Crankpin Bearing Width | 78 mm |

| 5 | Name of Vessel | MV ABBA |

ACTION TAKEN BY RA POWER SOLUTIONS TO REPAIR THE CRANKSHAFT OF DAIHATSU 6 DK-20:-

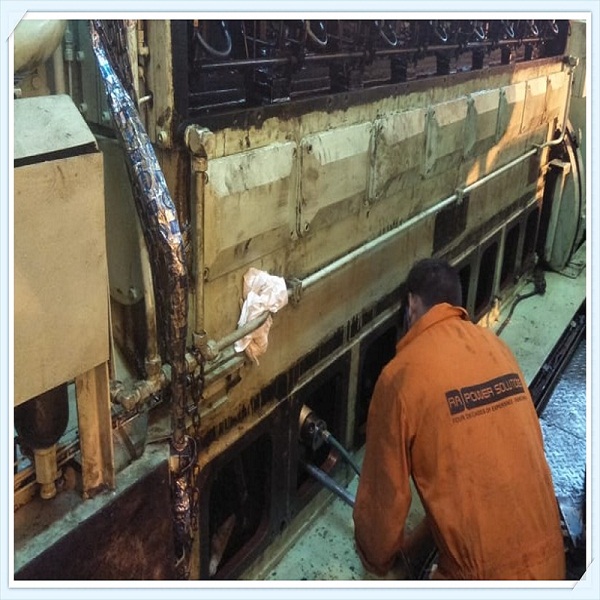

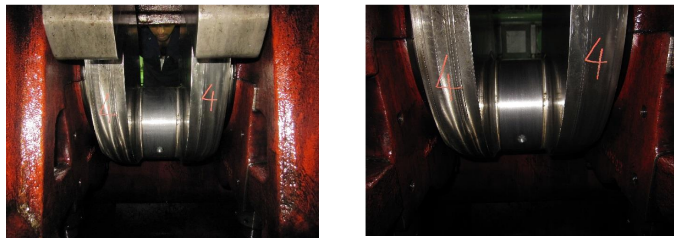

- Technicians on boarding the vessel inspected the crankshaft.

- The hardness of crankpin no.3 was observed within limits between 210 to 240 HB scale.

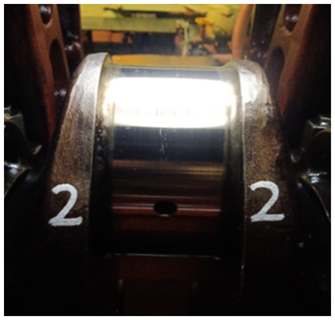

- After a thorough cleaning of crankpin No. 3, the MPI test was done and no cracks or abnormality was observed.

- Crankpin no. 3 was subject to dimensional inspection.

FOLLOWING ARE THE MAIN OBSERVATIONS:-

a) Minimum diameter observed – 169.10 mm

b) Maximum diameter observed – 169.33 mm

c) Total ovality -0.40 mm

The crankshaft was already undersized to 169.50 mm against the standard size of 170.00 mm.

ACTION TAKEN BY RA POWER SOLUTIONS FOR REPAIR OF CRANKSHAFT OF DAIHATSU 6 DK-20:-

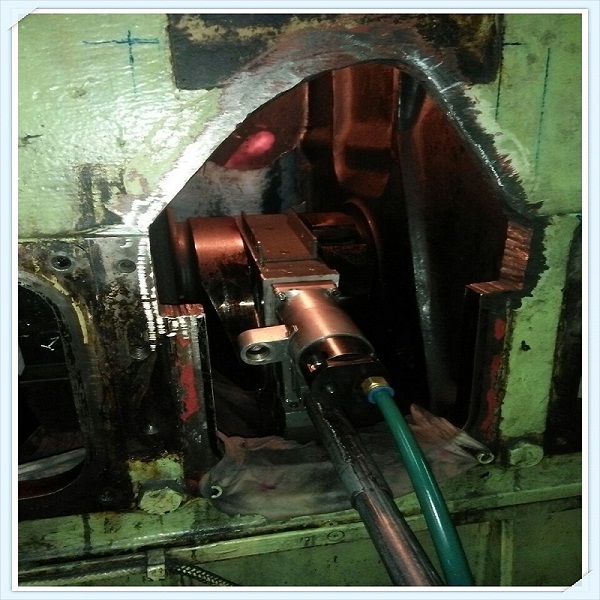

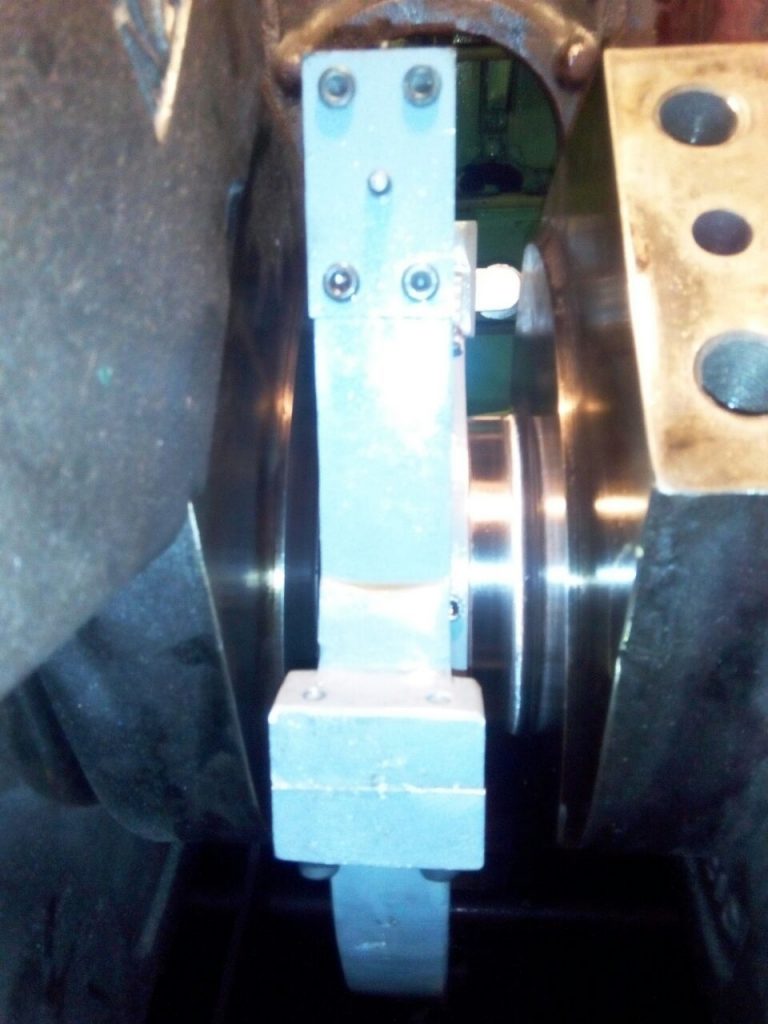

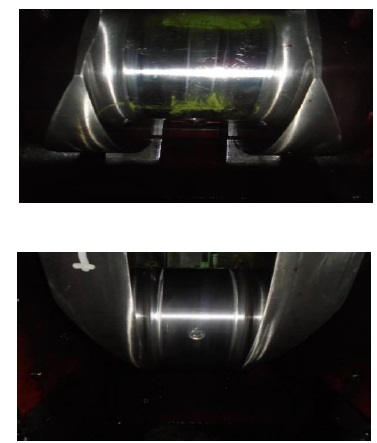

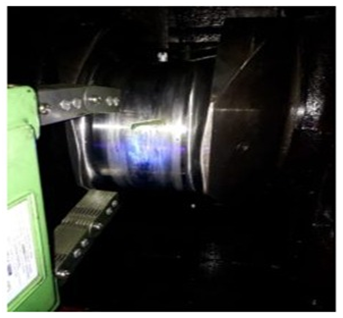

- The onsite crankshaft grinding machine was set up and grinding of crankpin no.3 was undertaken by reducing the diameter by 1 mm.

a) The minimum diameter observed after grinding – 168.98 mm

b) Maximum diameter observed after grinding – 169.00 mm

c)Total ovality observed after grinding – 0.02 mm

- After grinding crankpin no. 3, the engine was assembled and put on trial.

- We will be pleased to share the original pre and final machining inspection reports duly signed by the chief engineer of the vessel which has all the technical details required for the successful repair of the crankshaft.

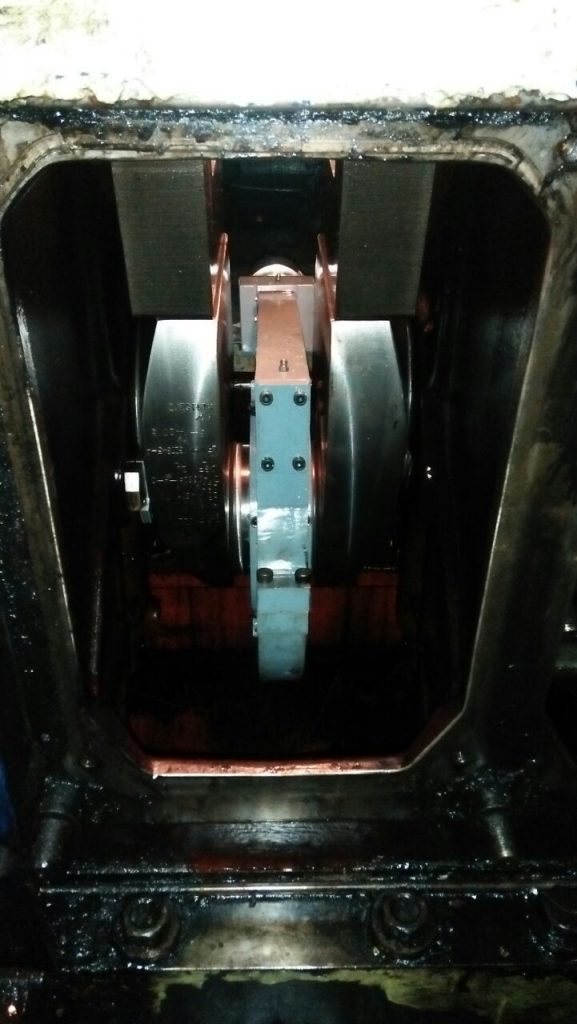

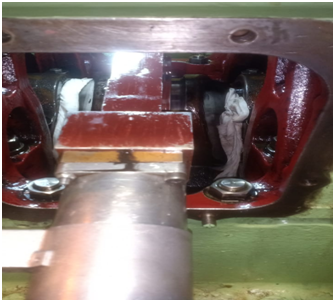

REPAIR OF CRANKSHAFT OF DAIHATSU 6 DK-20 HAVING CRANKPIN BEARING WIDTH OF ONLY 78 MM:-

It was possible for RA Power Solutions to successfully undertake repair of the crankpin having a bearing width of only 78 mm because we have the equipment which can be placed on the crankpin or main journal diameter having a bearing width of as small as 40 mm.

With this advanced technology and process, no other crankshaft repair company has due to which they either reject the crankshaft or recommend getting it repaired from the workshop.

We have been regularly executing the repairs in Greece, Moldova, Belarus, Australia, Austria, Belgium, Brazil, Cambodia, Colombia, Denmark, Ethiopia, Ghana, Haiti, etc.

This blog is written by Mr. Raj Shahani (Managing Director of RA Power Solutions India Pvt. Ltd.) and a highly experienced business leader with rich experience of more than 40 years in the field of Power, Heavy, and Shipping industry. He is Technical Adviser to many shipping and heavy industries across the globe.

Mr. Shahani is one of the most enthusiastic professionals and he has all the brilliance of an exemplary leader. He is an extremely effective coach and mentor of teams and is adept at providing leadership in a global, cross-cultural environment.

For more information on bearings for Daihatsu engine and Daihatsu crankshaft repair contact us at rajshahani@rapowersolutions.com or info@rapowersolutions.com or call us at +91 9582647131 or +91 9810012383.