RA Power Solutions is the world’s leader in the development, manufacturing, and supplying of onsite crankshaft grinders. We have already sold worldwide More than 70 onsite crankshaft machining equipment ranging from 35 mm to 700 mm in terms of diameter. Ours is the first company in the world that has changed the concept of crankshaft repair by making it simple and easy.

companies based in Europe, the UK, and Singapore projected on site crankshaft grinding and onsite crankshaft repair to be difficult and charged an exorbitant amount towards the repair from shipping companies, diesel power plants, and the industry using rotatory equipment. With the introduction of onsite portable, lightweight crankshaft grinding machines the companies are saving considerable amounts towards the cost of repairs and maintenance of crankshaft and engine in totality.

We have sold more than 70 crankshaft grinders to the shipping companies, industries, and repair workshops that have broken the monopoly of the European companies by offering on site crankshaft grinding and crankshaft polishing services with international standards and at low prices.

The crankshaft repair is recommended in case of the following problems:

- In case of bearing failure, bearing material gets stuck to the crankshaft surface.

- Overheating of crankpin and main journal which is evident by black/blue discoloration and development of local hard spots.

- Development of taper and ovality higher than the limits specified by the manufacturers.

- Dents and scoring on the crankpin or the fillet radius.

- Heat cracks

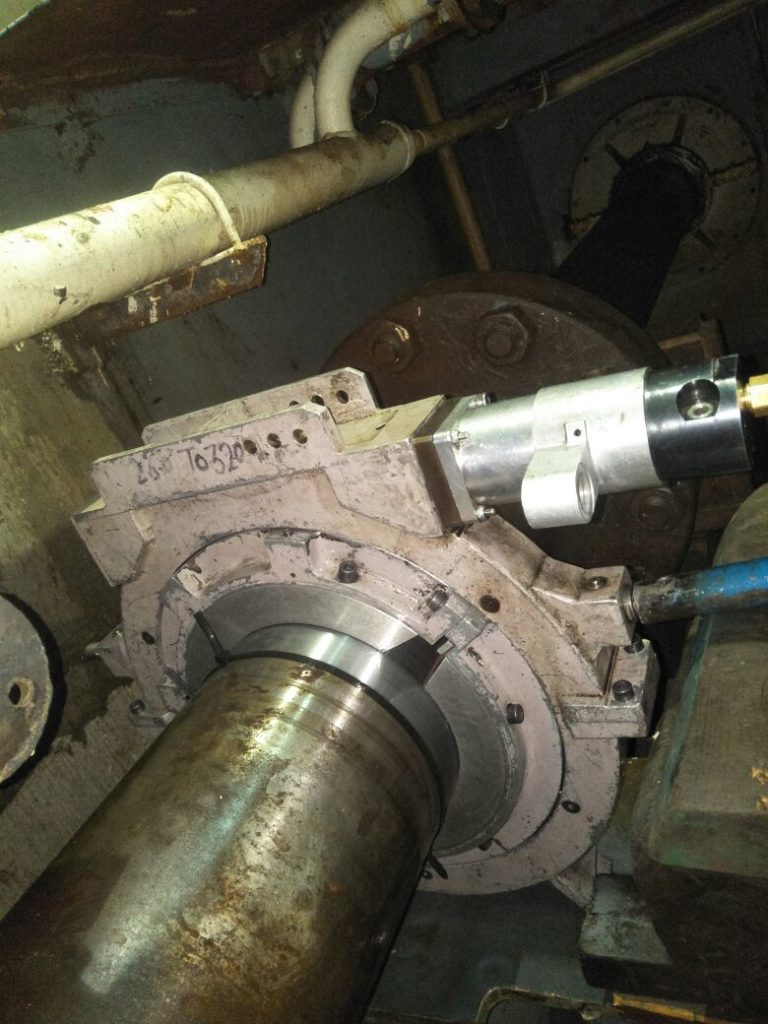

The onsite crankshaft grinding machine developed and manufactured by RA Power solutions is capable of repairing of crankshaft having all the problems including the problems mentioned above.

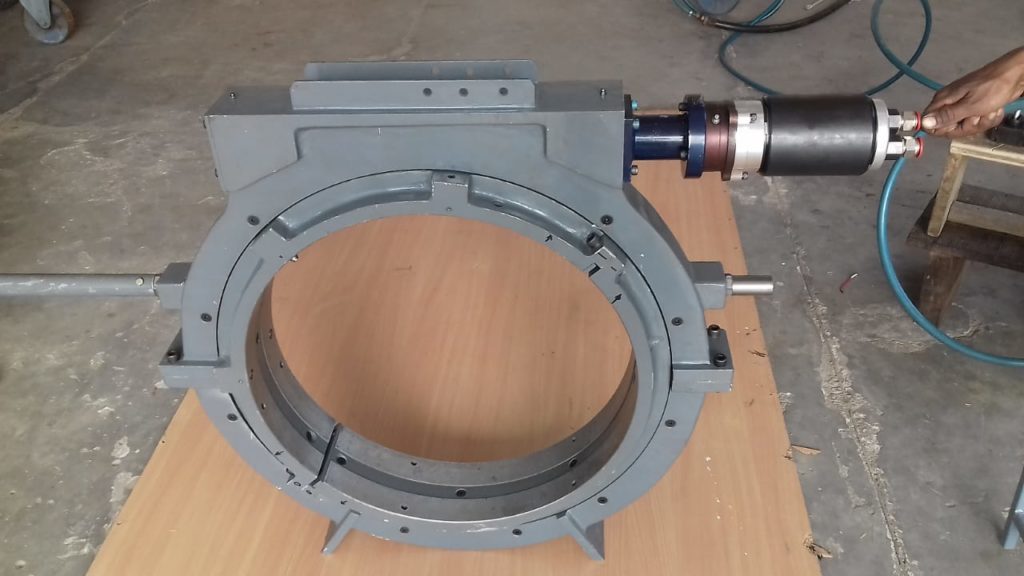

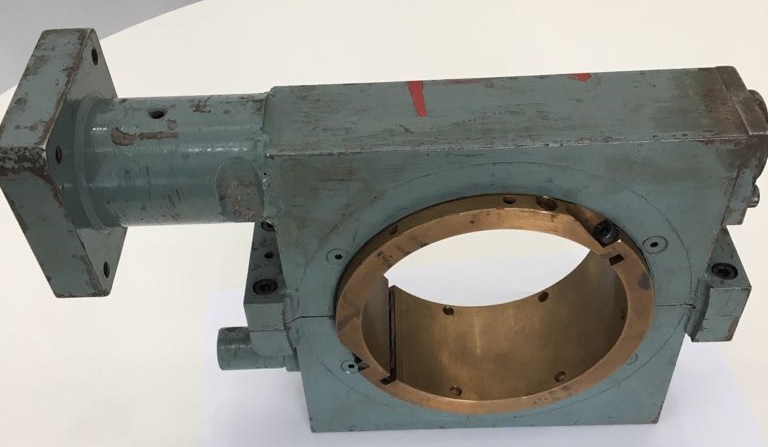

The on site crankshaft grinding and polishing machine has the following features:

- Lightweight, portable, and can be easily taken to the site all over the world.

- Machine is presently available in the range of 35 mm to 700 mm diameter. A higher range of machines is under development. Options for pneumatic and electric drives are available.

- Machine is supplied in powder-coated steel boxes with a provision of clamps to hold it in order to avoid damage during the transit from one site to another.

- Large information on the crankshaft of the popular engine and their model is shared with the client.

- Free training on-site is provided for the operation and maintenance of the crankshaft grinders.

The author is Mr. Raj Shahani, Managing Director of the company. He is having forty years of experience in providing on site engine repair services to companies all over the world. For saving the owner’s time and money, he has developed an on site crankshaft grinding machine.

For any information on onsite crankshaft grinding machine exporter, onsite crankshaft grinder manufacturer, and onsite machining of crankshaft please email us at rajshahani@rapowersolutions.com, or info@rapowersolutions.com, or call us at +91 9582647131 or +91 9810012383.