Yanmar Diesel Generator Model no 8N280L-EV

RA Power Solutions was approached by one of the largest shipping companies based in Athens Greece regarding the breakdown of the Crankshaft of YANMAR Diesel Generator Model no. 8N280L-EV. The vessel was to take a berth at Mundra port India and the stay of the vessel at the port was limited to only 13 hrs.

Action taken by RA Power Solutions for successful repair of Crankshaft of Yanmar Diesel Generator Model no. 8N280L-EV.

- As mentioned above we were given only 13 hrs of time at Mundra Port India to inspect the crankshaft and execute the repair. In this situation, we decided to depute a team of three technicians onboard the vessel instead of two technicians which is our normal practice.

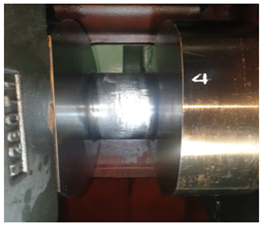

- After boarding the vessel, a detailed inspection of crankpin no. 4 which got damaged was conducted.

Following are the main observation:

- The diameter of crankpin no 4 was checked and the following dimensions were observed:

- Minimum diameter observed – 224.15 mm

- Maximum diameter observed – 225.00 mm

The above shows the ovality of 0.85 mm.

- The deep scoring marks on crankpin were observed as bearing got seized.

- The crankpin no. 4 was subject to hardness check and was found within limits except on few scattered points where it was observed in the range of 500 HB.

- The crankpin was subject to crack detection by high intensity magnaflux torch and no cracks or abnormally was observed.

- Due to the seizure of the crankpin bearing the radius fillet of both the sides was badly damaged.

Successful Repair of Crankshaft of Yanmar Diesel Generator Model no. 8N280L-EV in a short time of 13 hrs undertaken by RAP Engineers

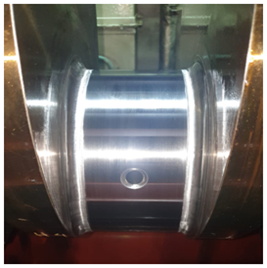

- Our technicians worked non stop and were able to successfully repair the crankpin no. 4 by under sizing and grinding it to 1.0 mm.

- After grinding & polishing following minimum & maximum crank pin diameter was maintained:

- Minimum diameter observed – 223.98 mm

- Maximum diameter observed – 224.00 mm

- The above reading shows the crankpin was undersized by 1.0 mm from 225.00 mm to 224.00 mm thus maintaining the ovality of only 0.02 mm which is far superior than the tolerance stipulated in the manufacturer’s manual.

- The formation of radius fillet at both ends was a big challenge as it was badly damaged and time available was limited. The radius fillet was also repaired successfully.

- The 1.0 m undersize crank pin bearing was available onboard the vessel.

- RA Power Solutions technicians also helped the ship technical staff in calibration of connecting rod, measurement of big end bearing, and other areas.

- It is normal for RA Power Solutions to take such challenging jobs where the damage to the crankshaft due to an accident is very serious and the time available is short.

- We have a team of technicians who are experienced to take on such challenging assignments. The availability of most modern onsite crankshaft grinding machine with RA Power Solutions also helps us to expedite the job and finish it in the minimum possible time.

- We use high capacity, lightweight, and compact Pneumatic Turbine to execute the repairs

For more details on the crankpin grinding machine email us at info@rapowersolutions.com, rajshahani@rapowersolutions.com, or Call at +91 9582647131,+91 9810012383.