RA Power Solutions is having more than forty years of experience in the field of repair, overhaul, and maintenance of high-capacity marine diesel engines installed on board the vessel and land-based diesel generating sets used for various applications. We are crankshaft specialists and have executed successfully onsite repair of crankshafts up to 700 mm diameter number exceeding more than 10,000 all over the world.

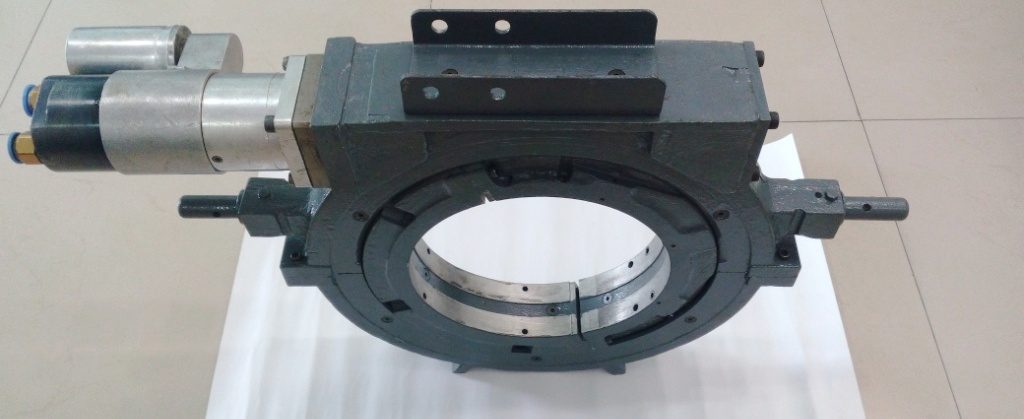

Cylindrical Shaft Grinding and Polishing Machine

Two decades back, RA Power Solutions developed and manufactured an onsite crankshaft grinding machine and onsite cylindrical shaft grinding machines having a range starting from 35 mm to 700 mm in terms of the diameter of the shaft on date more than 70 machines have been sold all over the world.

Our clients include companies providing services to industries and shipping companies, large industries, and workshops undertaking repairs of heavy equipment. The complete range of onsite crankshaft grinding machines and polishing machines is designed for high precision and a high volume of repair in a short duration.

It is a highly technological in situ grinding machine with a simple control system to deliver and maintain the international standards in terms of tolerances after grinding.

Construction of In Situ Crankshaft Grinding and Polishing Machine

The main casing of the onsite crankshaft grinding machine is made up of titanium steel which has a strong structure and high vibration absorption properties. This has been of great benefit, especially while undertaking grinding and polishing of crankshaft and all cylindrical shafts on board a moving vessel.

The other benefits are as follows:

- Keep the temperature constantly low

- Reduce the vibration on the machine

- Improvement in strength The advanced technique of the onsite crankshaft grinding machine makes grinding and polishing very easy

The in situ crankshaft grinding & polishing machine has the following capabilities:

- Range starting from 35 mm to 700 mm which covers crankshaft of most popular engines and their models.

- Lightweight, compact, and easy to carry to any destination.

- Easy to operate and maintain.

- Does not require any day-to-day maintenance.

- The crankshaft Grinding Machine is designed to maintain tolerance within 10 to 20 microns depending on the diameter of the shaft.

- RA value with the Surface finish of fewer than 0.2 micrometers is achieved.

- Compact nature of in situ crankshaft grinding and polishing machine facilitates to enter from even the smallest inspection window of the engine block.

- Vibration is less and with a low noise level.

- No heat is generated, easy to operate.

- Free onsite training is provided for the operation of in situ crankshaft grinding and polishing machines.

- Machine can be operated round the clock.

- Options Available for Pneumatic Drive or Electrical Drive.

- Highly recommended for crankshaft rebuilding, Cylindrical shaft grinding, and polishing.

The insitu crankshaft grinding and polishing machine is supported with complete data on crankshafts of popular makes and models of the engine giving the diameter, bearing width, and all the important parameters which are required for grinding of the crankshaft. The onsite crankshaft grinding and polishing machine is priced low and can be recovered in 2-3 grinding assignments.

For any details on crankshaft grinding, cylindrical shaft grinding and polishing machine, or crankshaft grinding machine manufacturers, please email us at rajshahani@rapowersolutions.com, or info@rapowersolutions.com, or call us at +91 9582647131 or +91 9810012383.