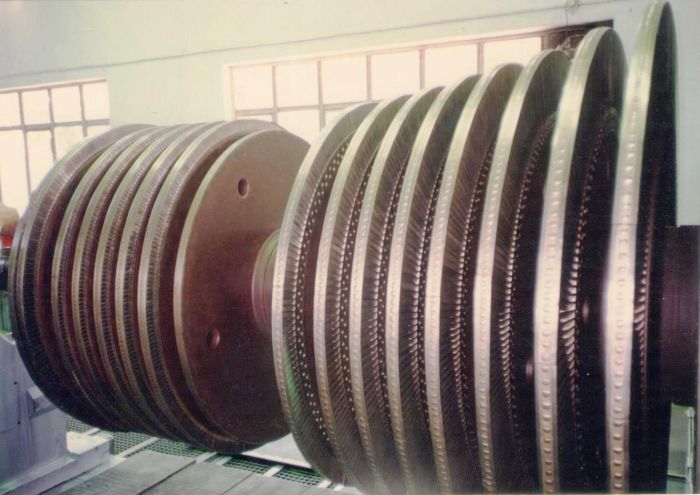

Failure of bearing due to over load or accident results to development of taper and ovality on turbine, alternator, rotor shaft. In certain cases the deep bearing line marks are developed and bearing surface becomes rough. This needs to be corrected.

RA Power Solutions undertake grinding and polishing of crankshaft, rotor shaft, turbine shaft, alternator from last 4 decades. We are the leaders in extending the grinding and repair services.

The main features of turbine, alternator, rotor shaft grinding and polishing are as following:

- Initial inspection of turbine, alternator, and rotor shaft is undertaken by experienced technicians. They carry all latest instruments to check dimensions, hardness, surface roughness, crack detection, taper and ovality. It is of great importance that proper inspection by Qualified and Experienced Engineer is conducted.

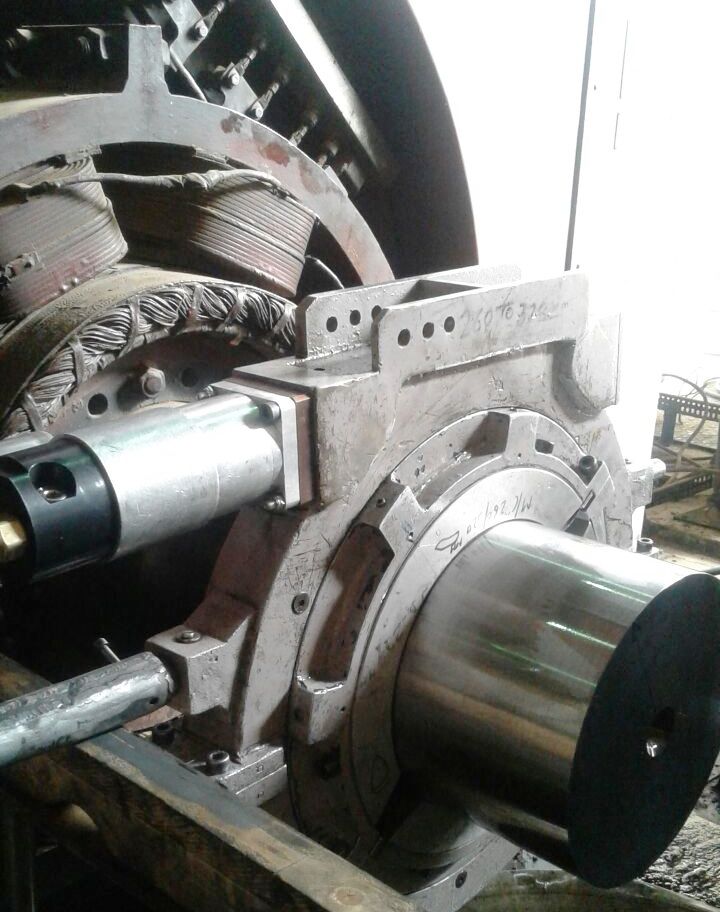

- Latest breed of turbine, alternator, rotor shaft grinding and polishing equipment is available with us having capacity up to 700 mm diameter.

- On site grinding and polishing equipment used by RA Power Solutions is light and compact. Easy to carry to site and can be fitted on the damaged diameter of turbine, alternator and rotor shaft. It is important as minimum disassembly of the parts is required.

- The turbine, alternator, rotor shaft grinding equipment is capable of maintaining close tolerance even up to 20 microns with surface finish of 0.15 Ra value which is far better then the international standard.

- All the repairs of turbine, alternator, and rotor shaft are executed with guarantee.

RA Power Solutions also manufactures white metal Babbitt bearing up to 1500 mm and rebabbitting of old bearings which get worn out or damage is done.

We have offered Onsite turbine shaft grinding services to many countries, including Bangladesh, Dubai, Singapore, Italy, the United Kingdom, South America, Ecuador, Nigeria, the Philippines, Columbia, the United Arab Emirates, and Qatar, etc.

Contact rajshahani@rapowersolutions.com, or info@rapowersolutions.com, or call us at +91 9582647131 or +91 9810012383 for more details on onsite turbine shaft grinding, on site crankshaft grinding, alternator shaft grinding and polishing.