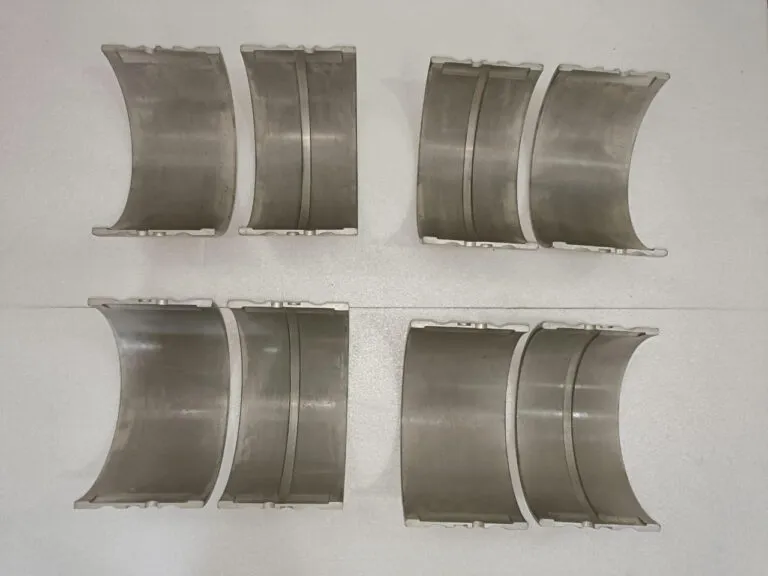

Crankpin Bearings are precision components placed between the crankshaft and the big end of the connecting rod. They enable smooth rotation while handling heavy, cyclic loads—critical for minimizing friction, wear, and heat in the engine’s dynamic environment.

Typically made as two-piece semi-circular shells, these bearings are manufactured from multi-layer steel with specialized overlays for durability and performance.

Why Crankpin Bearings Matter — Especially in Marine & Heavy-Duty Engines

On large diesel, marine, and industrial engines, crankpin bearings:

- Allow smooth, low-friction operation under extreme pressure.

- Distribute loads, absorb shocks, and prevent metal-on-metal contact.

- Help extend engine life and reduce costly downtime.

After crankshaft grinding or resizing, they often no longer fit—undersized crankpin bearings are essential in these cases. Unfortunately, such sizes are usually rare in the market, especially for older or less common engine models.

RA Power Solutions: Your Expert Source for Crankpin Bearings

With over four decades of experience, RA Power Solutions offers:

- A wide inventory of standard and undersize crankpin bearings for major engine makes, including Yanmar, Daihatsu, MAK, MAN, and others.

- Globally sourced tri-metal and plain bearings from Japan, Germany, and the UK

- Custom special-size manufacturing—especially valuable when standard undersize bearings aren’t available.

- Integration of grinding, supply, and commissioning under one provider—minimizing downtime and simplifying your project.

Types & Materials: What Makes a Crankpin Bearing Superior?

- Design: Most are use multi-layer constructions—steel backing with copper-lead alloy substrates and wear-resistant overlays that enhance conformity and embeddability.

- Lubrication: Bearings rely on hydrodynamic lubrication—an oil film separates moving surfaces. Poor oil supply or boundary lubrication leads to wear, cavitation, and early failure.

- Manufacturing types: Bearings can be standard or trimmed to undersize; some advanced options include polymer or sputtered tri-component coatings for enhanced durability.

When Do You Need Undersize Crankpin Bearings?

- Post-Grinding Fit

Grinding crankshaft journals removes damage and reduces size, so standard bearings no longer fit. - Obsolete Engine Models

Older or non-mainstream engines may lack available spare parts—undersize bearings become a critical solution. - Downtime Reduction

Having ready-to-ship bearings saves time and keeps operations on track—critical in marine, industrial, or power generation applications.

Keep Your Engines Running: Best Practice

| Strategy | Benefit |

| Assess bearing clearance accurately after grinding | Ensures proper oil film, prevents boundary lubrication |

| Choose the right material and layer configuration | Improves load resistance, wear life, and engine reliability |

| Opt for suppliers with custom undersize capability | Saves time, avoids sourcing hurdles for rare sizes |

| Prioritize reputable brands and tested parts | Reduces downtime and unexpected failures |

Connect with Us for Quality Crankpin Bearings

Need reliable crankpin bearings —standard or undersized—for Yanmar, Daihatsu, MAK, MAN, or other engine makes? RA Power Solutions is your global partner, offering precision parts and expert on site support.

✉ Email: info@rapowersolutions.com | info@rapowersolutions.com

Contact us at: +91 9582647131 or +91 9810012383

FAQs:

Crankpin bearings are precision components that support the connecting rod on the crankshaft, reducing friction and wear.

These are required after crankshaft grinding when journal diameters are reduced.

Improper lubrication, high loads, or misalignment are the most common causes of crankpin bearing failure.

We manufacture custom undersize and special bearings for obsolete or rare engine models.

Marine, industrial, and power engines such as Yanmar, Daihatsu, MAK, and MAN.