Good News for Shipping Companies, Power Plants and Repair Workshops.

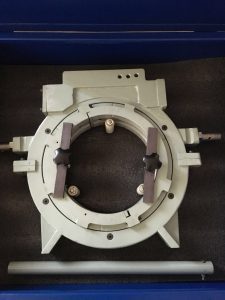

Crankshaft grinding machine up to 700 mm diameter is designed, developed and manufactured by RA Power Solutions. Machine is having following features:

Crankshaft Grinding Machine Design: Machine is portable; light weight and can be carried to the site. Nowadays, there is no need of disassembly of complete engine.

Operation of Crankshaft grinding machine: The machine is operated pneumatically or by electrical motor. The design is so simple and machine can be easily operated by a skilled technician.

Quality: Crankshaft grinding machine is capable of maintaining close tolerance in terms of taper and ovality up to 20 microns and can also achieve the surface finish as per the International standards.

Training: RA Power Solutions Pvt. Ltd. provides training to the clients, and technicians for the duration of 3 days. The assembly, operation, and maintenance of the machine are explained.

Cost of Machine: Presently, shipping companies and power plants having high-capacity diesel generating sets have no option but to call for technicians from the companies based in Norway, Singapore, UK and various countries by paying exorbitant amount and travel expenses. The Crankshaft grinding machine is manufactured by RA Power Solutions is very reasonably priced and the cost can be recovered in 1 or 2 jobs of repairs.

We have supplied more than 60 In situ crankshaft grinding machines all over the world which are performing satisfactory.

WORKING OF ONSITE CRANKSHAFT GRINDING MACHINE (400-450mm)

For more information on revolution in crankshaft grinding contact us today by please email us at rajshahani@rapowersolutions.com, or info@rapowersolutions.com, or call us at +91 9582647131 or +91 9810012383.