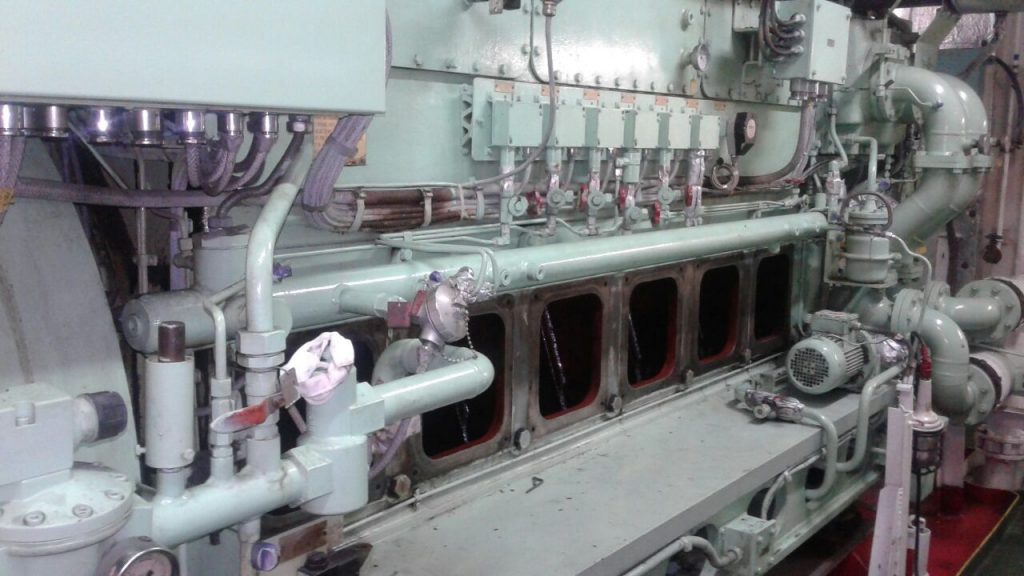

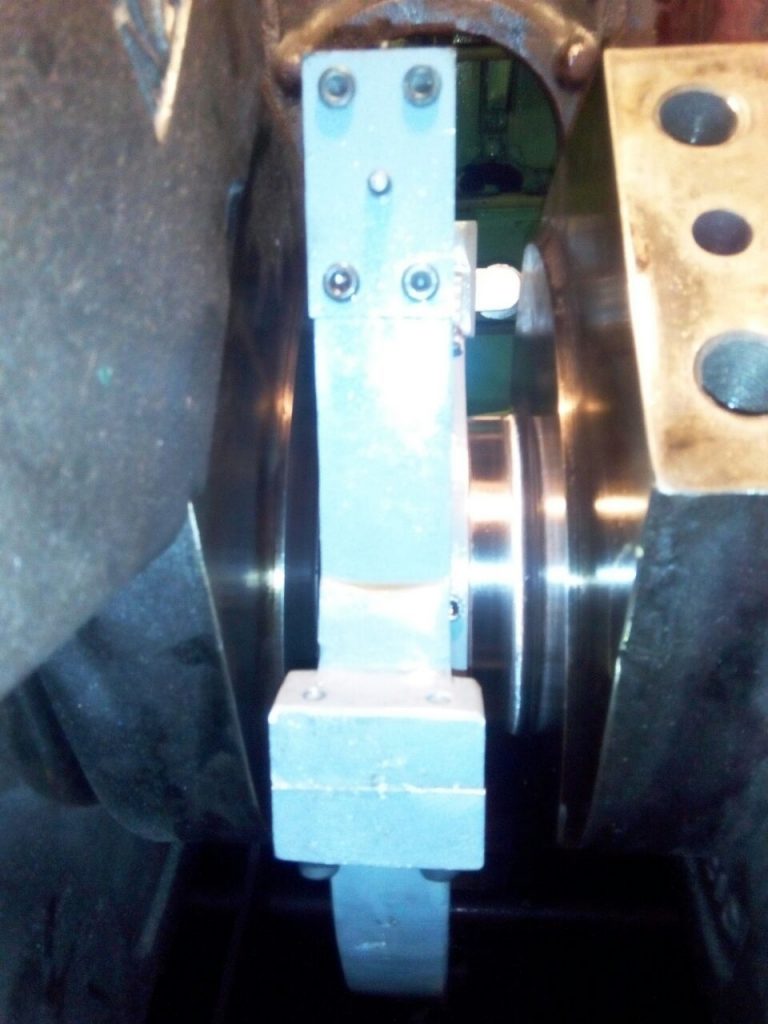

RA Power Solutions undertakes Onsite Repair and Grinding of Crankshaft up to diameter of 700 mm. The experience technicians travel with light weight latest design of On site Crankshaft Grinding Machine to execute the Crankshaft Repair. The On site Crankshaft Grinding Machine has following benefits to the clients.

The Benefits:

- You do not need to remove the Cranks shaft from the engine or press.

- We save your time: – some of these repairs can be carried out as little as 24 hours.

- We save your money: – The engine does not have to be stripped down and transported or reassembled. The savings on this alone are usually very significant.

- We keep your plant running: – Downtime is minimized so that you can be back into operation and earning money sooner.

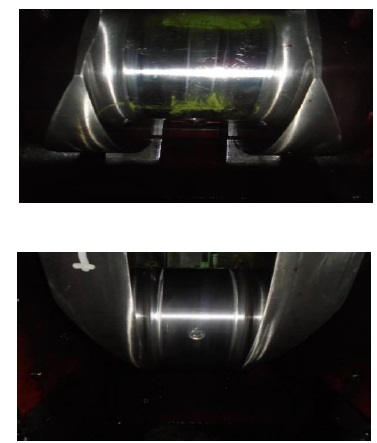

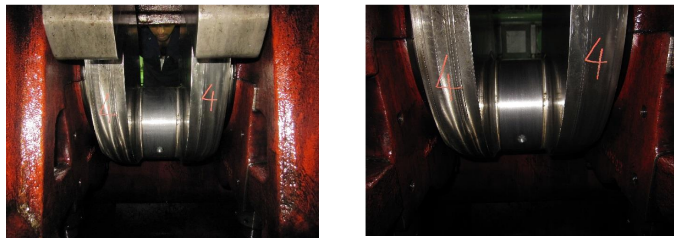

- Machining and polishing of Crankshaft and Crankpin are carried to OEM tolerances and surface finish specifications.

- We cover standard Crankshaft diameter ranging from 30 mm to 700 mm.

- Our patented orbital equipment rotates around damaged crankpin journal using the radius as a datum.

- We can also Hone and Polish your crankpin if the damage is slight or you just want to improve the surface finish up to 0.3 micron Ra Value.

For more information on on site crankshaft grinding, onsite crankshaft repair on vessel, onsite crankshaft machining and polishing, onsite crankshaft maintenance services, or insitu crankshaft grinding please email us at rajshahani@rapowersolutions.com, or info@rapowersolutions.com, or call us at +91 9582647131 or +91 9810012383.