Crankshaft is considered to be a heart of the engine. It is important that all the parameters recommended by engine manufacturers are strictly maintained for continuous and satisfactory performance of the engine.

It is observed that crankshaft failure can happen at any time in spite of excellent maintained engine. Secondly, due to continuous running of a diesel engine wear and tear, development of taper and ovality, pitting, and rough surface is developed. This needs to be corrected. By introduction of onsite crankshaft grinding and crankshaft polisher machine, RA Power Solutions has made onsite crankshaft grinding and polishing easy. Now there is no need of removing the crankshaft and sending it to the workshop for repairs.

With our revolutionary onsite crankshaft grinding and onsite polishing machine, it is possible to do the repair crankshaft onsite.

Crankshaft grinding & crankshaft polishing machine has the following features:

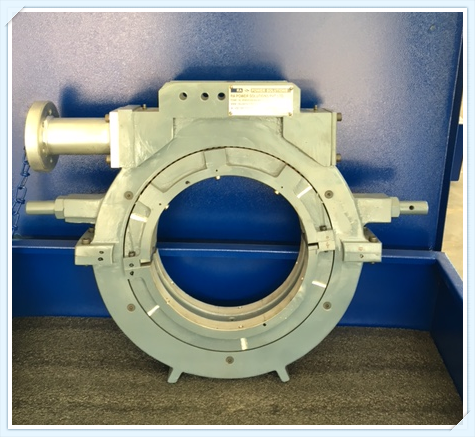

- The crankshaft grinding machine is available in the range of 30 mm to 700 mm which covers crankshafts of small to high-capacity engines.

- The performance of onsite crankshaft grinding machine manufactured by RA Power Solutions is a proven, solution-focused approach with guaranteed results in terms of tolerances. By using onsite crankshaft grinding machine, shipping companies, diesel power plant, and drydocks have reduced the downtime considerably and save money which really matters due to competition.

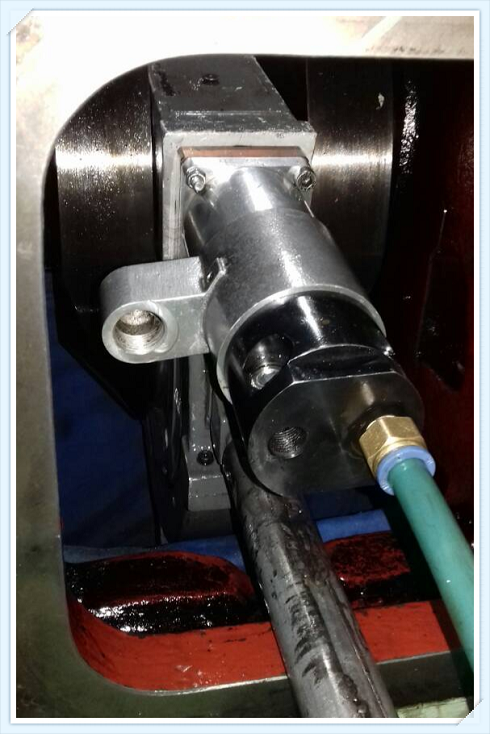

- The onsite crankshaft grinding and polishing is undertaken by the same equipment. Every time engine is open for major overhauling, crank pin and main journal of crankshaft can be polished to remove the bearing line marks and to improve the surface finish. This increases the life of bearing and avoids crankshaft from breakdown.

- The crankshaft grinding and crankshaft polishing machine is designed to provide workshop quality service onsite, drydock or even while sailing of the vessel. The crankshaft grinding equipment has minimum vibrations, manufactured of titanium alloy which absorbs the vibrations. This facilitates to maintain close tolerances of crankpin and main journal of the crankshaft even while sailing of the vessel.

- 24/7 global support services are provided for any guidance for operation and maintenance of the onsite crankshaft grinding machine. A training program is designed and arranged onsite covering all the aspects of the operation and maintenance of the machine.

- Machine is priced low and has the capability to generate high revenue in a short time. The onsite crankshaft grinding machine is supplied complete in all respect and ready to operate with consumables sufficient to repair one crankshaft.

- RA Power Solutions maintains a large databank of crankshafts of reputed diesel engine manufacturer and their models.

The author is Mr. Raj Shahani, Managing Director of the company. He is having 40 years of experience in grinding of crankshaft, polishing of crankshaft and all services related to repair of engines and supporting equipment. He has designed and developed the portable crankshaft grinding machine to save time and money.

We will be pleased to share more information regarding onsite crankshaft grinding and polishing machine, please email us at rajshahani@rapowersolutions.com, or info@rapowersolutions.com, or call us at +91 9582647131 or +91 9810012383.