RA Power Solutions was recently approached by a diesel power plant based in South America having Wartsila 12V32 and Wartsila 18V32 diesel generating sets.

A serious accident took place due to failure of cylinder liner resulting in to the damage of various parts including lower and upper engine block of Wartsila 18V32 engine. On investigation by RA Power Solutions technicians it was observed that upper and lower engine block suffered severe multiple cracks measuring to total 2900 mm in length and damage of casting into small pieces measuring 300 X 460 mm.

Various options were discussed and it was decided to replace the lower and upper crankcase. The cost of replacement of damage lower and upper engine block of Wartsila 18V 32 was exorbitant with a delivery period of 9 months. RA Power Solutions proposed to repair the multiple cracks and damaged portion by metal stitching and metal locking process. This is a cold process of crack repair and has been followed by our technicians in number of installations all over the world during our service to the industry for last four decades.

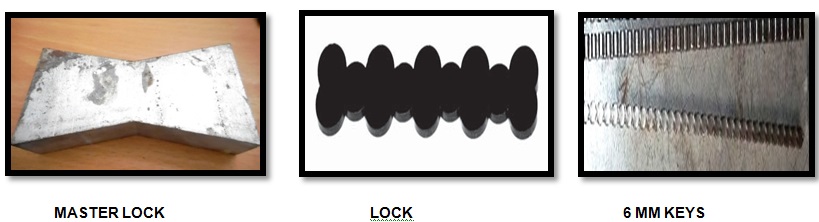

The damaged portion of the engine block was given a discipline profile and new piece of casting having similar metallurgical properties as of the parent material was placed and metal stitched using the latest design of metal stitching locks and keys. The multiple cracks were properly marked by our technicians using the latest MPI equipment to identify the cracks. The multiple cracks were also repaired by metal stitching and metal locking process.

RA Power Solutions also undertook the onsite grinding of crankshaft which got damaged due to accident and re-assembled the engine in 16 days time. All these repairs were conducted in-house with the onsite portable equipments which were carried to the site by the technicians. Perhaps no other company in the world can offer all repair services under the same roof.

The engine is performing satisfactory.

RA Power Solutions specializes in cast iron repairs, utilizes advance metal stitching and metal locking processes that are ideal and most suited for this type of crack repair.

RA Power Solutions takes the pride to announce that in our four decades of experience, we were able to save millions of dollars of end users by undertaking the onsite repairs of damaged parts avoiding the expenses towards the cost of new parts which are exorbitantly priced with long delivery.

We have a dedicated team to undertake the repair of crack and damaged engine components. It is possible to undertake metal stitching and metal locking for repairs of crack on a moving vessel.

Technicians can join the vessel in short time as they carry seaman passport. As an Indian company we are respected for our sincerity, experience and lowest cost.

For more information on engine block repair and damage engine block repair, please email us at rajshahani@rapowersolutions.com, or info@rapowersolutions.com, or call us at +91 9582647131 or +91 9810012383.