The Introduction of Onsite Crankshaft Grinding Machine, Insitu Crankshaft Polishing and Grinding Machine, and Crankshaft Machining, there is no need of removing the Crankshaft and sending it to the work shop as now it is possible to undertake crankshaft grinding and crankshaft repair with revolutionary design of Onsite Crankshaft Grinding Machines manufactured by RA Power solutions.

Onsite grinding of crankshaft without removing it from the engine block is undertaken by taking the reference of radius fillet.

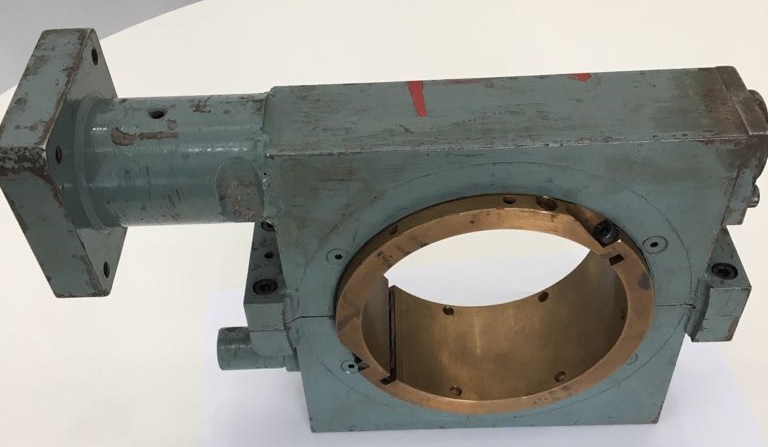

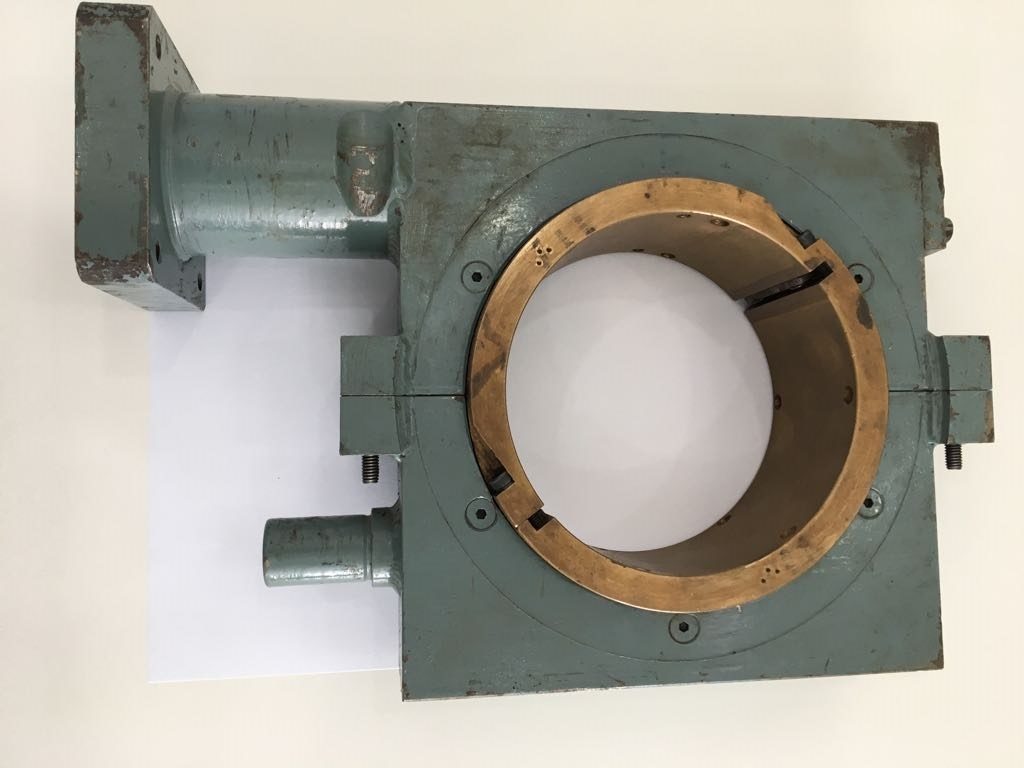

The onsite crankshaft grinding machine is placed on both side of the radius of the crankpin and tool rotates undertaking grinding and polishing of crankshaft. This process of crankshaft grinding by insitu crankshaft grinding machine is successful generally for the diameter of the crankpin of 200 mm and above having a bearing width of 125 mm minimum.

For the smaller diameter of the crankpin, it is not possible to undertake the grinding by taking the reference of radius fillet due to the space constraints.

RA Power Solutions has introduced a compact, easy to operate onsite crankshaft grinding machine which is suitable for grinding and polishing of small diameters of the crankpin above 30 mm. The crankpin bearing width can be as small as 30 to 40 mm. With this latest technological advance crankshaft grinding machine, it is easy to grind the smaller diameter of the crankpin having smaller crankpin bearing width.

The crankshaft grinding machine has the main features of machining, grinding and polishing of the crankpin. The tolerances in terms of taper, ovality, and surface finish are maintained far better than the manufacturer’s recommendation.

RA Power Solutions having 4 decades of experience in in situ crankshaft grinding have executed successfully repair of more than 11,000 crankshaft all over the world and are leaders in this field.

For your requirement of portable onsite crankshaft machine, crankshaft grinding machine, crankshaft grinding, and insitu crankshaft grinding machine you may write us at info@rapowersolutions.com.