In case of accident of Crankshaft in recent past, it was necessary to disassemble the crankshaft from the engine block or housing, pack it and send it to the designated workshop.

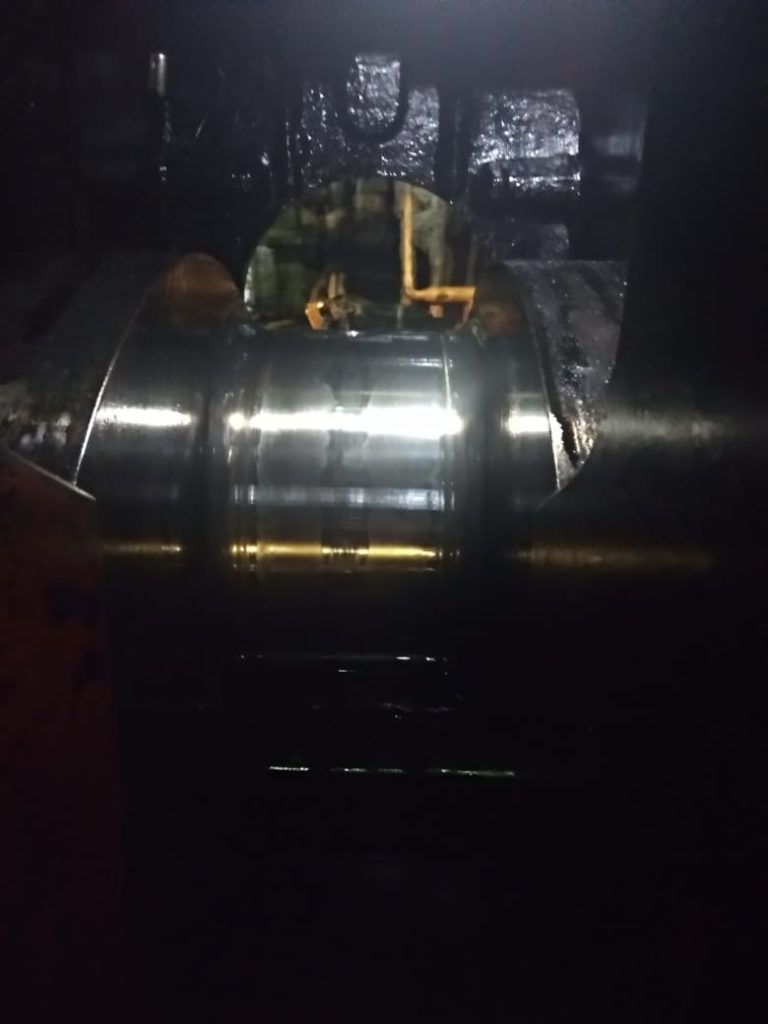

The Introduction of Onsite Crankshaft Grinding Machine, Insitu Crankshaft Polishing and Grinding Machine, and Crankshaft Machining, there is no need of removing the Crankshaft and sending it to the work shop as now it is possible to undertake crankshaft grinding and crankshaft repair with revolutionary design of Onsite Crankshaft Grinding Machines manufactured by RA Power solutions.

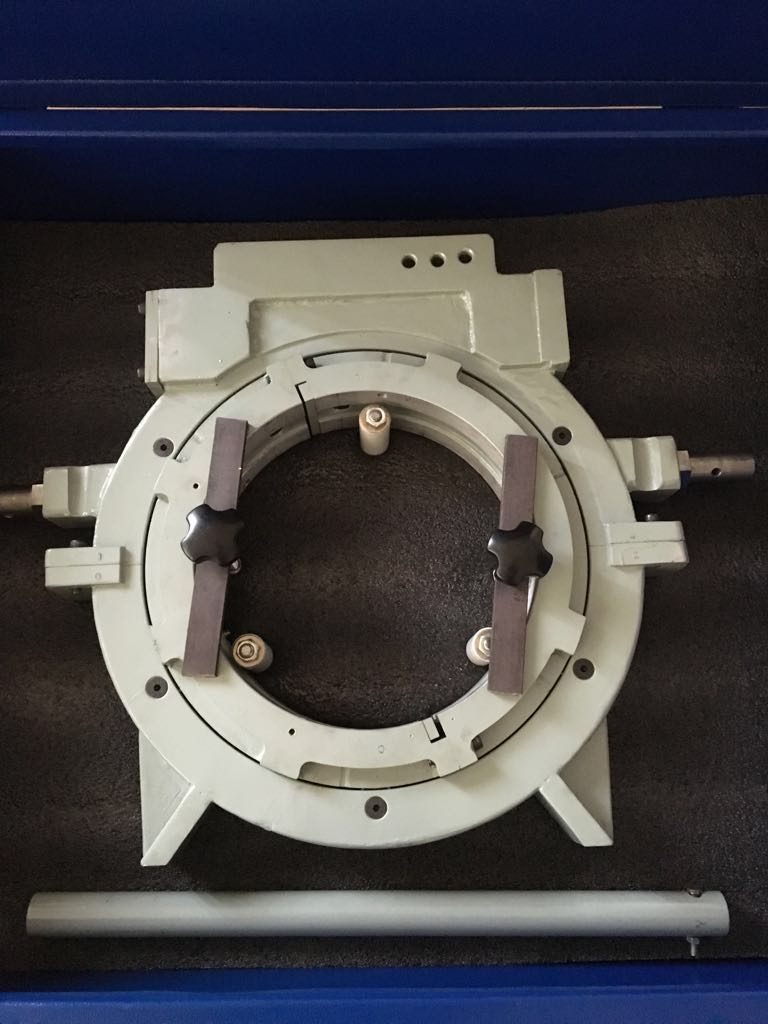

The Onsite Crankshaft Grinding Machine has been developed out of our experience of Crankshaft repair of Forty Years. The Machine is Lightweight and can be taken to the Site. It has the following Features.

- Onsite Crankshaft Grinding Machine, Insitu Crankshaft Polishing, and Grinding Machine is manufactured by RAP after extensive research, development, and our experience.

- The Machine in the Initial Years was used by our technicians for In-house applications. Now from last ten years Machine is sold in open market all over the world.

- The Insitu Crankshaft Grinding and Polishing Machine is user-friendly and can be operated by any person having basic machining knowledge.

- The Machine is capable and is designed to maintain the close dimensions and Geometrical tolerances as per the manufacturers requirement.

- Presently Onsite Crankshaft Grinding Machine is manufactured for the diameter of the Crank-pin and Main Journal of the Crankshaft ranging from 30 mm to 700 mm.

- Crankshaft Grinding Machine is manufactured out of Titanium Alloy which is lightweight and can be easily carried to the Site.

- The Machine is capable of working on a Vessel while it is moving.

- Training forms an integral part of the Crankshaft Grinding Machine. Training onsite is provided.

- We have sold more than seventy machines all over the world and are priced cheapest in the International Market.

For more details on insitu crankshaft grinding equipment, portable crankshaft grinding machine or onsite crankshaft grinding and polishing please email us at rajshahani@rapowersolutions.com, or info@rapowersolutions.com, or call us at +91 9582647131 or +91 9810012383.