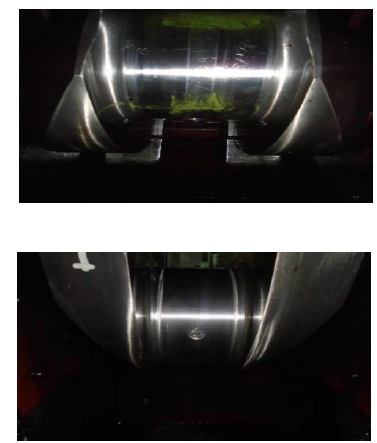

The crankshaft is the heart of the engine and is the most important/expensive component. It is necessary that the crankpin journal and main journal of the crankshaft are periodically inspected and polished. This not only enhances the life of the bearing but saves the crankshaft from any damage in case it is properly polished.

The oil film between the crankpin/main journal and bearings is too thin while the engine is in operation. In case the main journal and crankpin have roughness, burr, pitting, and line marks it can result in the discontinuation of oil film and failure of bearing causing damage to the crankshaft.

RA Power Solutions during the working on crankshafts of marine Engines for the last four decades have observed that non-conventional methods for polishing of main journal and crank pin journal are adopted to put the engine back in operation.

The non-conventional methods used are as follows:

I) Polishing of crankpin journal and main journal by Jute rope.

II) Polishing of crankpin journal and main journal by various grinding and polishing mediums.

We observed that following these unconventional and nontechnical processes for polishing the crankshaft does not remove the line marks or the various other abnormalities which do get developed. In some cases, since this process has no control excessive taper and ovality are created resulting in the failure of the bearing and crankshaft.

Crankpin and Main Journal Polishing Made Easy:

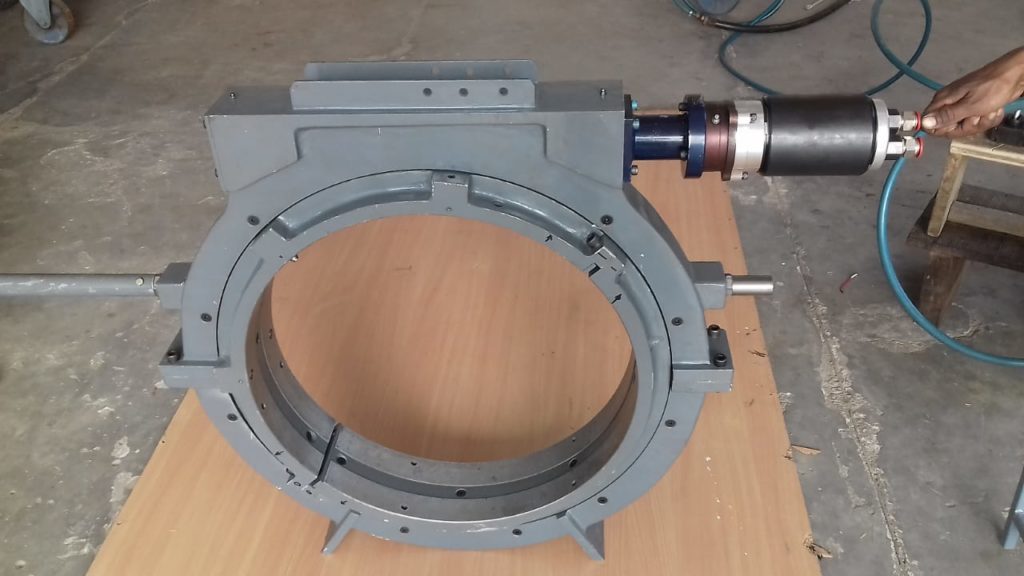

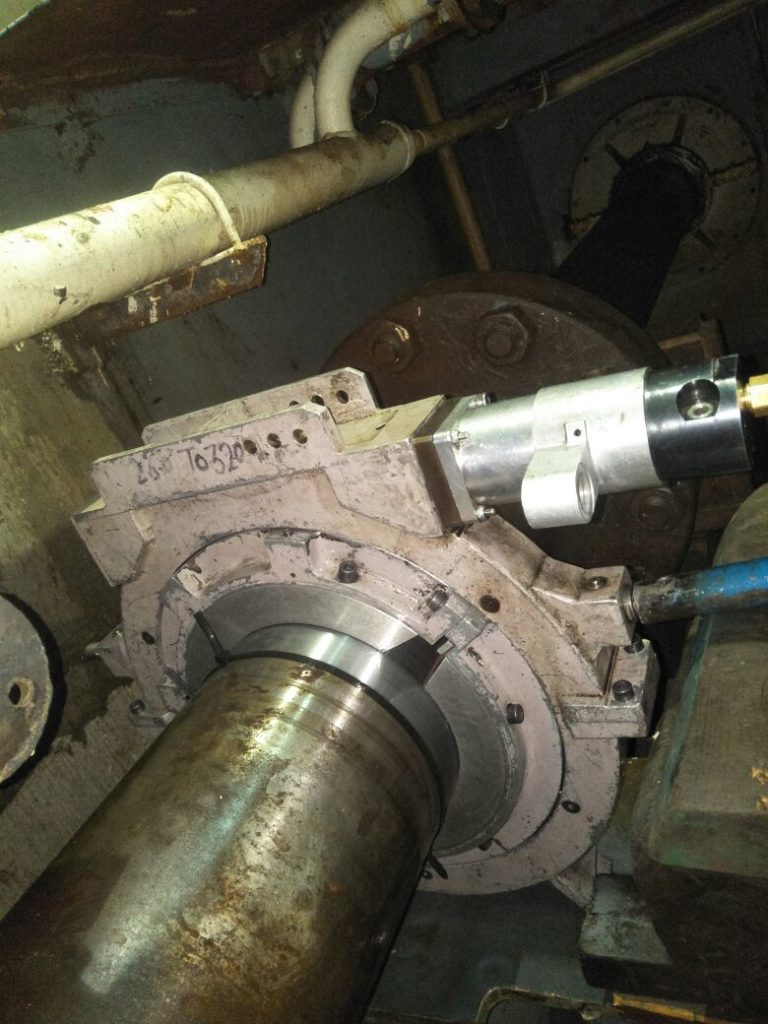

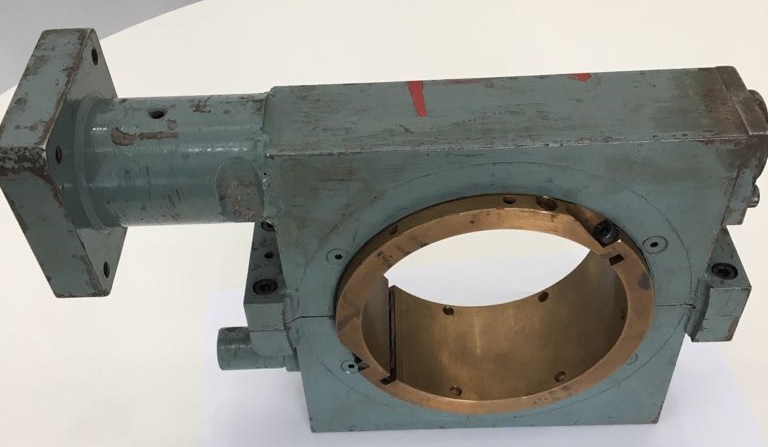

RA Power Solutions by introducing a lightweight, compact onsite crankshaft polishing machine has made the crankshaft repair process simple with minimum downtime of the engine. The polishing and grinding machine are inserted from the engine block and a polishing crankpin is undertaken. The onsite crankshaft grinding and polishing machine is capable of maintaining a surface finish better than the international standards i.e. 0.2 RA value.

Suggestions:

RA Power Solutions strongly suggest that the polishing of the crankpin should be undertaken periodically as a routine maintenance process. This will not only extend the life of the bearings but also save the crankshaft from any major breakdown.

We offer two options to our clients either they can call our technicians who will visit their site with the portable on-site Crankshaft polishing equipment and undertake the polishing of the crankshaft. Alternatively, we also manufacture onsite crankshaft polishing machines which are simple to operate. More than 70 onsite crankshaft grinding and polishing machines have been sold all over the world.

RA Power Solutions offers a cutting-edge crankshaft polisher machine that revolutionizes the process of crankshaft polishing. The crankshaft polisher machine is designed to enhance the crankshaft’s performance, durability, and overall efficiency, ultimately optimizing the engine’s performance.

Our commitment to quality and innovation makes their crankshaft polisher machine a go-to solution for clients seeking top-notch results. Trust in RA Power Solutions to deliver excellence in crankshaft polishing, meeting the highest industry standards and exceeding customer expectations.

This blog is written by Mr. Raj Shahani (Managing Director of RA Power Solutions) having more than forty years of experience in the field of onsite repair of high-capacity engines. After extensive trials and research, he has developed onsite crankshaft grinding and polishing equipment for saving the crankshaft from rejection.

For any queries about main journal grinding, onsite crankshaft polishing services, crankshaft journal machining, and Crankshaft Polisher machine please email us at rajshahani@rapowersolutions.com, or info@rapowersolutions.com, or call us at +91 9582647131 or +91 9810012383.