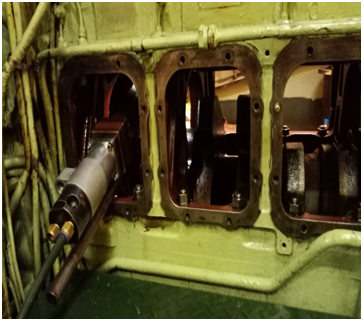

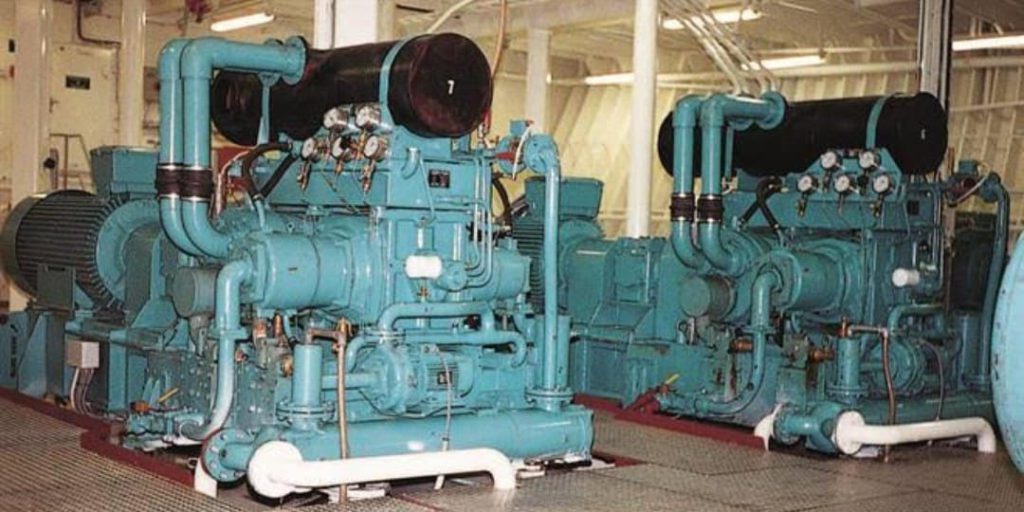

MITSUBISHI engines are widely used in operation for shipping and heavy industries. Use of genuine spare parts of MITSUBISHI leads to satisfactory performance of the engine even in typical working conditions.

MITSUBISHI ENGINE SPARE PARTS

RA Power Solutions as an engineering company plays an important role in providing spare parts of main engine and auxiliary engines to our clients irrespective of location of engines where it is installed.

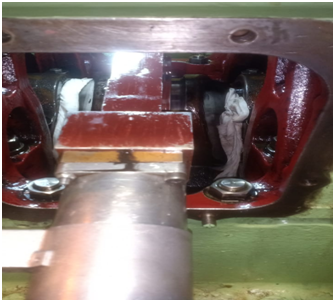

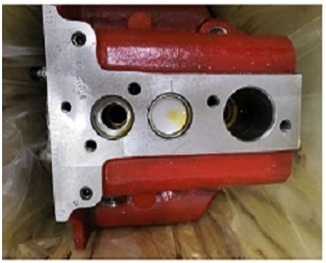

We maintain a large range of MITSUBISHI engine spare parts in stock for your perusal and purchase. Understanding the quality requirement of MITSUBISHI diesel engine spare parts, each and every part offered by us is thoroughly inspected, calibrated and properly identified as per the manual before dispatch to the client.

ADVANTAGES OF BUYING MITSUBISHI ENGINE SPARE PARTS FROM RA POWER SOLUTIONS:-

We are ISO 9001:2015 company dealing in the maintenance of medium and high capacity engines understanding the importance of quality of each part.

All the parts supplied by us are guaranteed for satisfactory performance.

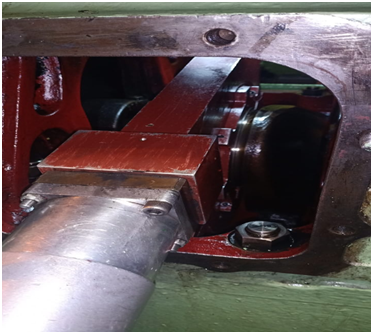

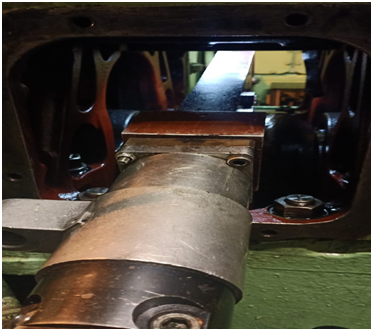

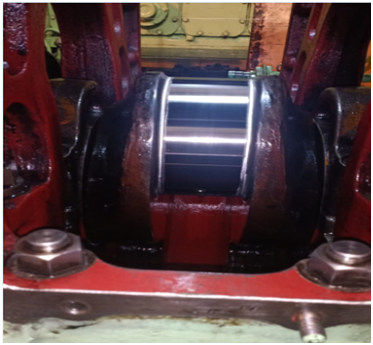

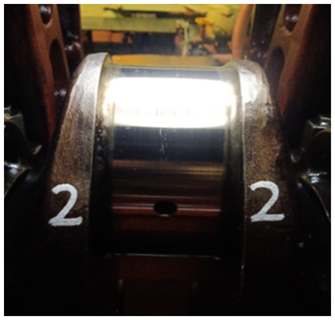

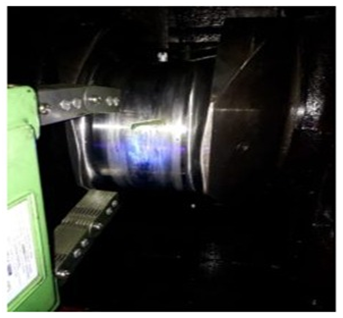

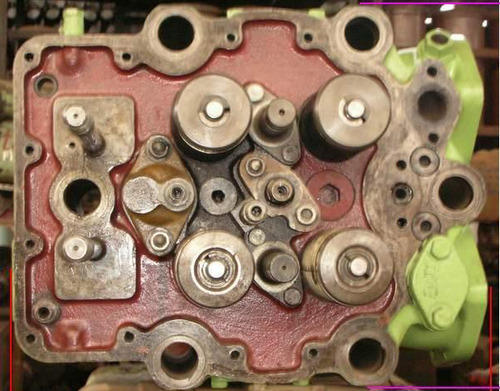

We specialize in delivering the parts of MITSUBISHI engine models which are old and are no more manufactured by MITSUBISHI plant. We maintain large stock of crank pin and main journal bearings. Special and undersize Bearings of Mitsubishi engines are readily available.

We have observed our clients face a lot of difficulties in sourcing the spare parts of engines which are not in the manufacturing range of MITSUBISHI. We have the stock of spare parts of old models of engines and most of the critical parts like pistons, liners, heads are available with us.

The popular models of the MITSUBISHI diesel engine.

FEW OF THEM ARE MENTIONED BELOW:-

L2E/L3E

S3L/S3L2

S12A2/S12H/S12N/S12R

S16N/S16R

S4/S4L2/ S4Q/ S4Q2/ S4S/S4S-DT

D04FR

S6A/S6A2/S6A2/S6A3/S6B/S6B3/S6N/S6R/S6R2

S8N

S6S/S6S-DT

6D14/6D15/6D16/6D22/6D24/6D31/6D34

K3A/K3B/K3C/K3D/K3E/K3F/K3G/K3H

K4C/K4D/K4E/K4F

4DQ50

S3F

S4F

KE70/KE75

S4E/S4E2

S6E/S6E2

S2E/S2E2

S3E/S3E2

Spare parts of MITSUBISHI diesel engine are largely exported by us all over the world including Dubai, Greece, Maldives, Malaysia, Singapore, Madagascar, Nigeria, South America, UAE, Germany, Monaco, Qatar, Srilanka, Bangladesh, Italy, Spain, Czech Republic, UK, Philippines etc.

This blog is written by Mr. Raj Shahani (Managing Director of RA Power Solutions India Pvt. Ltd.).

Mr. Shahani is a highly experienced business leader with rich experience of more than 40 years in the field of Power, Heavy and Shipping industry. He is Technical Adviser to many shipping and heavy industries across the globe.

Mr. Shahani is one of the most enthusiastic professional and he has all the brilliance of an exemplary leader. Mr. Shahani is an extremely effective coach and mentor of teams and is adept at providing leadership in a global, cross-cultural environment.

For more information on Spare parts of Mitsubishi engine, spare part of mitsubishi diesel engine, and

Spare parts for Mitsubishi & Alfa Laval Purifier, contact us at rajshahani@rapowersolutions.com, or info@rapowersolutions.com, or call us at +91 9582647131 or +91 9810012383.