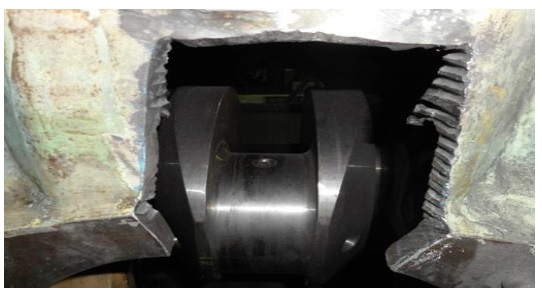

The repair of broken engine block, turbocharger casing, and heavy cast iron parts can be successfully repaired by metal stitching, metal locking, and metal surgery process.

The repair of crack and repair of damaged casting by welding process is now completely outdated and is not recommended for repair of damaged cast metal and cast iron parts. In fact, it is observed that in certain cases repair by welding results in more serious damage due to the generation of heat and stress during the process of welding. RA Power Solutions have been undertaking repairs of damaged engine block, steel components repair, cast iron repairs, and all types of cast components by metal stitching and metal locking process for the last four decades.

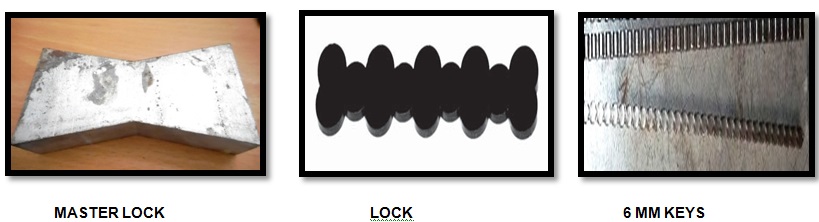

We have a separate and dedicated team of technicians who have the capability to undertake the onsite repair of crack and damage casting by using portable tools and high-quality consumables (locks and keys ) which are imported by us from the UK.

Advantages of crack repair and damage casting, cast iron repair by metal stitching, and metal locking process:

- It is possible to undertake crack repair and repair of damage casting by metal stitching and metal locking process onsite. Hence there is no requirement of transporting the cracked or damaged components to the workshop.

- In most cases, there is no requirement for the disassembly of equipment.

- We possess portable tools to execute the repairs on-site.

- The time duration for the repair of crack and damaged cast components by metal lock and metal stitching is low.

- Metal Stitching and Metal Locking is a permanent crack repair method as no heat is generated which is associated with welding.

- The crack and damaged area after repair by metal locking and metal stitching process is restored to its original profile and is also recommended for gas or watertight repair.

- Repairs are undertaken with the guarantee.

The repair by metal stitching and metal locking process can be undertaken of cast iron, aluminum parts including the following:

- Damaged turbocharger casing.

- Pump casing and gearboxes.

- Fixing Cracked engine block, cam covers, cylinder liners, turbine casings, and all components.

- Heavy industrial and mining equipment.

For a detailed repair process of damaged casting by metal locking, damaged engine block, metal stitching, broken engine block repair, and metal surgery please email us at rajshahani@rapowersolutions.com, or info@rapowersolutions.com, or call us at +91 9582647131 or +91 9810012383.