Crankshaft repair is required in case of the following abnormalities observed in the crankshaft

- Development of taper and ovality in crankpin and main journal of the crankshaft in access of tolerances stipulated by the manufacturer.

- Development of bearing line marks, pitting, and rough surface.

- Damage of radius profile due to accident or seizure of bearing of crankpin or main journal.

- Development of crack and variation in hardness of the crankpin and main journal of the crankshaft.

- Loss of alignment of the crankshaft.

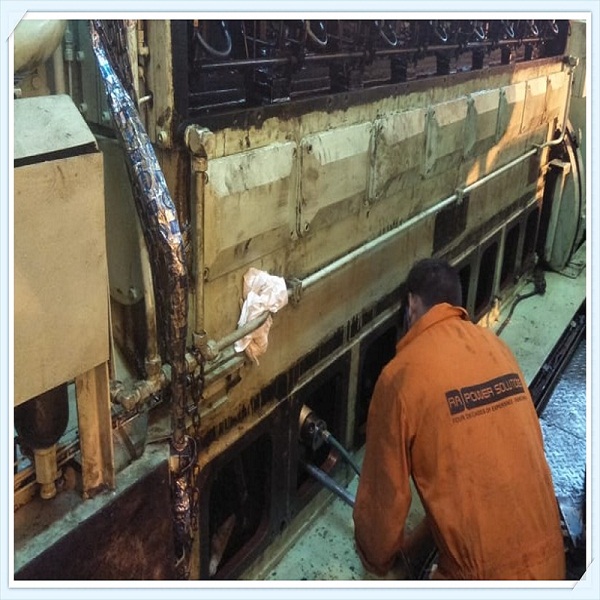

Crankshaft repair is undertaken by RA power solutions of the crankpin and main journal of the crankshaft diameter ranging from 35mm to 700mm. Crankshaft repair is undertaken by experienced technicians who have been specifically trained in our workshop on a dummy crankshaft, the company has experience of more than four decades in crankshaft repair services.

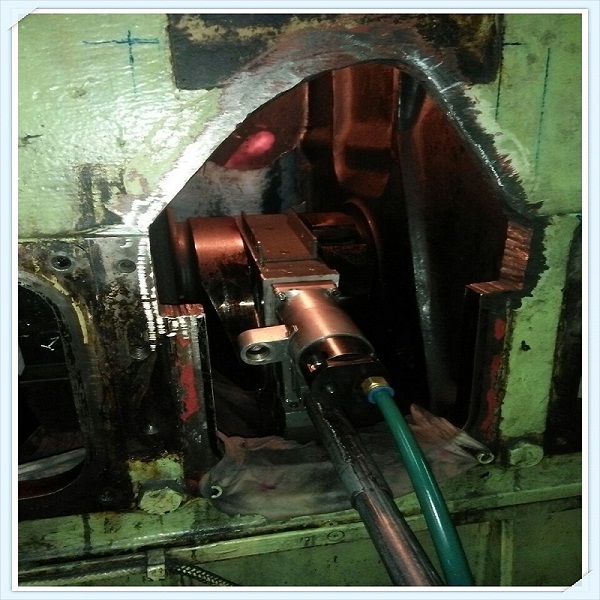

The on-site grinding equipment designed and manufactured by RA power solutions can maintain a close tolerance after crankshaft grinding within 0.02mm and the surface finish which is far superior to international standards. The crankshaft grinding machine has a main frame manufactured out of titanium steel which makes it lighter and vibration-free during operation. The grinding of the crankshaft is possible even while sailing of the vessel and there is no requirement of holding the vessel at anchor or a port for crankshaft repair.

RA Power Solutions is a leading provider of specialized crankshaft repair services and innovative crankshaft repair tools. With a team of highly skilled technicians and engineers, we offer comprehensive solutions for repairing damaged or worn-out crankshafts in various industries. From onsite inspections to comprehensive repairs, we are equipped to handle all aspects of crankshaft maintenance. Our advanced crankshaft repair tools, designed with precision and durability in mind, streamline the process, guaranteeing swift yet reliable service.

All the crankshafts repaired by RA power solutions are guaranteed for a satisfactory performance we have successfully executed more than 10,000 crankshaft repair jobs. The services of crankshaft grinding and crankshaft repair are offered at low cost and our technicians carry CDC of Indian origin, Panama, and Pallav.

Contact numbers for rajshahani@rapowersolutions.com, info@rapowersolutions.com, and +91 9582647131 and +91 9810012383 are available for more information on crankshaft repair services.